What Is Reverse Engineering?

Reverse engineering is the process of analyzing a system to create a representation of its components and their relationships.

This can be done through a variety of techniques, such as disassembling the system, studying the source code, or observing the system’s behavior.

Reverse engineering is often used to understand how a system works, to find vulnerabilities, or to create compatible products.

There are many reasons why someone might want to reverse engineer a system.

Some of the most common reasons include:

- To understand how a system works.

This can be useful for a variety of purposes, such as debugging, troubleshooting, or improving the system’s performance. - To find vulnerabilities. Reverse engineering can be used to identify security vulnerabilities in a system.

This information can then be used to patch the vulnerabilities and protect the system from attack. - To create compatible products. Reverse engineering can be used to create products that are compatible with existing systems.

This can be useful for a variety of purposes, such as creating new software applications or hardware devices.

Reverse engineering can be a complex and time-consuming process.

However, it can be a valuable tool for understanding how systems work and for finding vulnerabilities.## What is Reverse Engineering? Understand the Art of Deconstructive Innovation

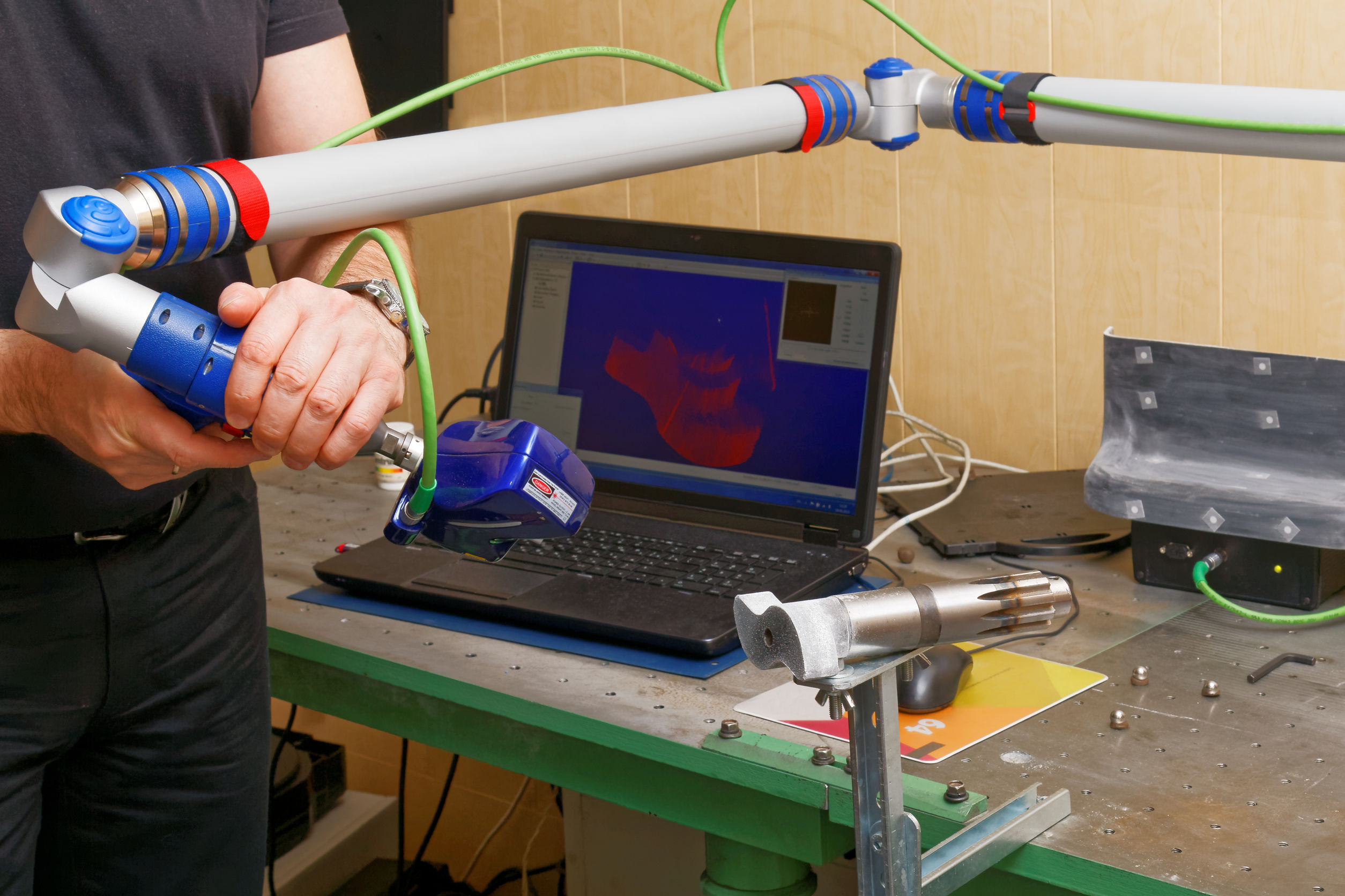

Reverse engineering, the process of deconstructing a product, system, or software to understand its design, function, and implementation, is a powerful technique with vast applications across various industries and engineering domains. This comprehensive guide delves into the world of reverse engineering, exploring its intricacies, benefits, and diverse uses.

Executive Summary

Reverse engineering has evolved as a transformative approach for businesses to gain competitive advantages. By meticulously analyzing the design and functionalities of existing products, companies can uncover hidden features, identify potential flaws, and derive valuable insights to enhance their own designs or develop innovative solutions.

Introduction

In the burgeoning technological landscape, understanding the inner workings of products and systems is crucial for innovation and problem-solving. Reverse engineering empowers engineers, researchers, and entrepreneurs to break down complex systems, comprehend their structural and functional aspects, and leverage these insights to spur innovation.

FAQs

- What are the Key Objectives of Reverse Engineering?

- Deciphering design principles and mechanisms behind existing products

- Identifying opportunities for improvement and cost reduction

- Creating compatible products or components

- What Industries Benefit the Most from Reverse Engineering?

- Electronics and Semiconductor Industry

- Automotive Engineering and Manufacturing

- Software Development and App Analysis

- What Ethical Concerns need to be Considered?

- Respecting intellectual property rights and patents of original designers

- Avoiding the manufacturing of clones or counterfeit products

- Adhering to industry standards and regulations

Subtopics of Reverse Engineering

Disassembly and Inspection

This initial step involves physically dismantling the target product into its constituent components for meticulous examination. Engineers meticulously inspect each part’s form, fit, and function to unravel its design and manufacturing techniques.

- Form: Precisely measuring the dimensions, shapes, and structural details

- Fit: Analyzing the interconnections between components

- Function: Evaluating how each part contributes to the overall functionality of the device

Material Analysis

Advanced analytical techniques, such as spectroscopy and microscopy, are employed to ascertain the precise composition and properties of the materials used in the product. Understanding the material’s characteristics, such as strength, durability, and conductivity, provides valuable information for design optimization and material selection in future developments.

- Elemental composition: Determining the primary and trace elements present using techniques like X-Ray Fluorescence or Atomic Absorption Spectroscopy

- Microstructure analysis: Visualizing the grain structure, defects, and other microstructural features using optical or scanning electron microscopy

- Mechanical properties testing: Measuring properties like tensile strength, hardness, and toughness to evaluate the material’s performance

Functional Analysis

This stage involves testing and evaluating the system’s or software’s behavior under various conditions to comprehend its functionality and limitations. Engineers employ a combination of automated testing tools and manual inspection techniques to probe the system’s response to specific inputs, conditions, and edge cases.

- Input and output analysis: Tracing the flow of inputs and outputs to identify the system’s functional dependencies

- State analysis: Analyzing the system’s behavior and transitions between different states

- Performance evaluation: Assessing metrics such as speed, efficiency, and accuracy

Logical Analysis

For software and digital systems, logical analysis entails studying the code structure, algorithms, and data structures to decipher the underlying logic and problem-solving strategies employed. This involves tracing the execution flow, identifying control structures and loops, and analyzing the manipulation of data.

- Code structure analysis: Examining the organization and structure of the codebase, including modules, classes, and dependencies

- Algorithm analysis: Uncovering the algorithms used for solving specific tasks and assessing their efficiency and complexity

- Data Flow Analysis: Tracking the movement and transformation of data throughout the system

Documentation

The culmination of the reverse engineering process is the creation of detailed documentation that comprehensively presents the findings and insights gained. This documentation serves as a valuable resource for understanding the product’s design, function, and potential areas for improvement.

- Technical specifications: Precisely documenting the components, materials, and functional characteristics of the product

- Design and implementation details: Describing the design choices, algorithms, and problem-solving approaches used in the product

- Recommendations and analysis: Providing insights into potential enhancements, cost-saving opportunities, or vulnerabilities identified through the analysis

Conclusion

Reverse engineering is an indispensable tool that empowers engineers and innovators to gain deep insights into existing products and systems, fostering groundbreaking advancements and propelling technological progress. By understanding the complex interplay of design principles, materials, and functionality, we pave the way for cutting-edge innovation and enhanced product development.

Relevant Keyword Tags

- Reverse Engineering

- Product Analysis

- System Design

- Innovation

- Intellectual Property