The Power of Predictive Maintenance in Industry 4.0 with AI

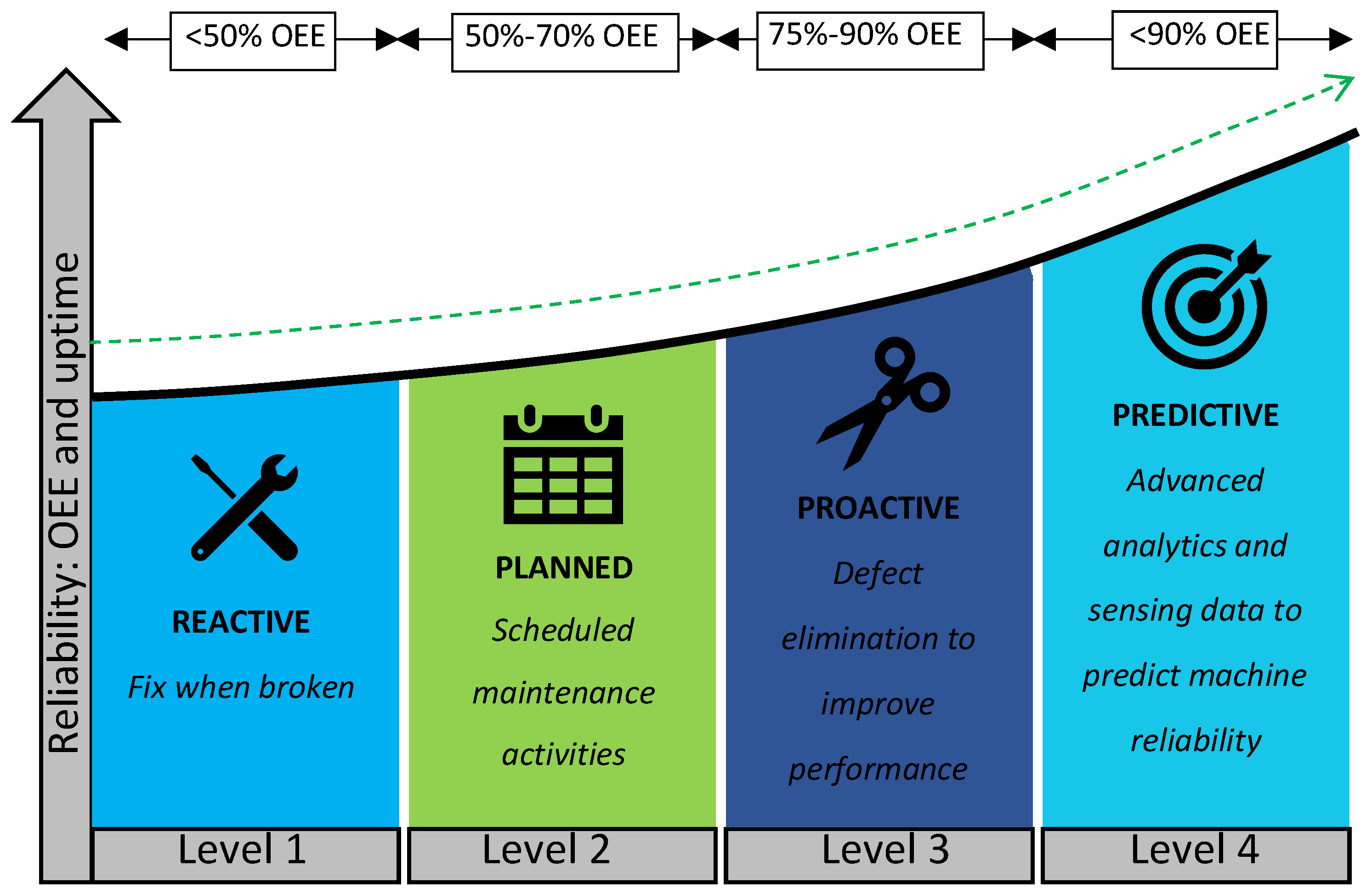

Predictive maintenance is a maintenance strategy that uses data and analytics to predict when equipment is likely to fail. This allows businesses to schedule maintenance before the equipment fails, which can help to prevent costly downtime and improve efficiency.

In Industry 4.0, predictive maintenance is becoming increasingly important as businesses adopt new technologies such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies can help to collect and analyze data from equipment, which can then be used to develop more accurate predictive models.

AI can help to improve predictive maintenance by:

- Identifying patterns in data that humans may not be able to see. AI algorithms can be trained to identify subtle patterns in data, which can help to identify potential problems before they become major issues.

- Automating the process of data analysis. AI can automate the process of data analysis, which can free up maintenance teams to focus on other tasks.

- Providing real-time insights. AI can provide real-time insights into the condition of equipment, which can help businesses to make better decisions about when to schedule maintenance.

Predictive maintenance is a powerful tool that can help businesses to improve efficiency and reduce downtime. When combined with AI, predictive maintenance can be even more effective. Businesses that adopt predictive maintenance can gain a significant competitive advantage in Industry 4.0.

Benefits of Predictive Maintenance in Industry 4.0

There are many benefits to using predictive maintenance in Industry 4.0, including:

- Reduced downtime: Predictive maintenance can help to prevent unplanned downtime by identifying potential problems before they become major issues.

- Improved efficiency: Predictive maintenance can help businesses to improve efficiency by scheduling maintenance during off-peak hours or when production is slow.

- Lower maintenance costs: Predictive maintenance can help businesses to lower maintenance costs by avoiding unnecessary repairs.

- Improved safety: Predictive maintenance can help to improve safety by identifying potential hazards before they cause accidents.

- Increased productivity: Predictive maintenance can help to increase productivity by reducing downtime and improving efficiency.

Conclusion

Predictive maintenance is a powerful tool that can help businesses to improve efficiency, reduce downtime, and lower maintenance costs. When combined with AI, predictive maintenance can be even more effective. Businesses that adopt predictive maintenance can gain a significant competitive advantage in Industry 4.0.## The Power Of Predictive Maintenance In Industry 4.0 With Ai

Predictive maintenance (PdM) is a maintenance strategy that uses data to predict when a machine or component will fail. This information can then be used to schedule maintenance tasks before the failure occurs, thereby preventing unplanned downtime and lost production.

PdM is a key component of Industry 4.0, the fourth industrial revolution. This revolution is characterized by the use of advanced technologies to create a more efficient, automated, and interconnected manufacturing environment. PdM can help companies achieve the benefits of Industry 4.0 by:

- Reducing unplanned downtime: PdM can help companies identify and address potential problems before they cause a breakdown. This can significantly reduce unplanned downtime, which can cost companies millions of dollars per year.

- Improving efficiency: PdM can help companies optimize their maintenance schedules, thereby improving efficiency. By scheduling maintenance tasks only when they are necessary, companies can avoid wasting time and resources on unnecessary work.

- Increasing productivity: PdM can help companies increase productivity by preventing breakdowns that can lead to lost production. By keeping machines and equipment running smoothly, companies can maximize their output.

Executive Summary

Predictive maintenance is a powerful tool that can help companies achieve the benefits of Industry 4.0. By using data to predict when machines or components will fail, companies can prevent unplanned downtime, improve efficiency, and increase productivity.

Introduction

Predictive maintenance (PdM) is a maintenance strategy that uses data to predict when equipment or components will fail. PdM is a key component of Industry 4.0, which is the fourth industrial revolution. Industry 4.0 is characterized by the use of advanced technologies to create a more efficient, automated, and interconnected manufacturing environment.

FAQ

What is predictive maintenance?

Predictive maintenance is a maintenance strategy that uses data to predict when equipment or components will fail. This information can then be used to schedule maintenance tasks before the failure occurs, thereby preventing unplanned downtime and lost production.

How does predictive maintenance work?

Predictive maintenance works by collecting data from sensors that are attached to equipment. This data is then analyzed to identify patterns and trends that can indicate that a failure is likely to occur.

What are the benefits of predictive maintenance?

The benefits of predictive maintenance include:

- Reduced unplanned downtime

- Improved efficiency

- Increased productivity

- Reduced maintenance costs

- Improved safety

The Benefits of PdM using AI in Industry 4.0

Benefits of Predictive Maintenance Using AI in Industry 4.0:

- Improved accuracy and reliability: AI can help to improve the accuracy and reliability of predictive maintenance models by identifying and accounting for a wider range of factors that can affect equipment performance.

- Real-time monitoring and analysis: AI can be used to monitor and analyze data in real-time, which can help to identify potential problems before they become serious.

- Automated decision-making: AI can be used to automate the decision-making process, which can help to reduce the risk of human error and improve the efficiency of maintenance operations.

Key Pieces of each benefit:

- Improved accuracy and reliability:

- AI can help to identify and account for a wider range of factors that can affect equipment performance.

- AI can learn from historical data to improve the accuracy of its predictions.

- AI can be used to develop more complex and sophisticated models that can capture the nuances of equipment behavior.

- Real-time monitoring and analysis:

- AI can be used to monitor and analyze data in real-time.

- AI can identify potential problems before they become serious.

- AI can send alerts to maintenance personnel when potential problems are identified.

- Automated decision-making:

- AI can be used to automate the decision-making process.

- AI can help to reduce the risk of human error.

- AI can improve the efficiency of maintenance operations.

Conclusion

Predictive maintenance is a powerful tool that can help companies achieve the benefits of Industry 4.0. By using data to predict when machines or components will fail, companies can prevent unplanned downtime, improve efficiency, and increase productivity.

Keyword Tags

- Predictive maintenance

- Industry 4.0

- Artificial intelligence

- Machine learning

- Data analytics