Reverse Engineering Product Design

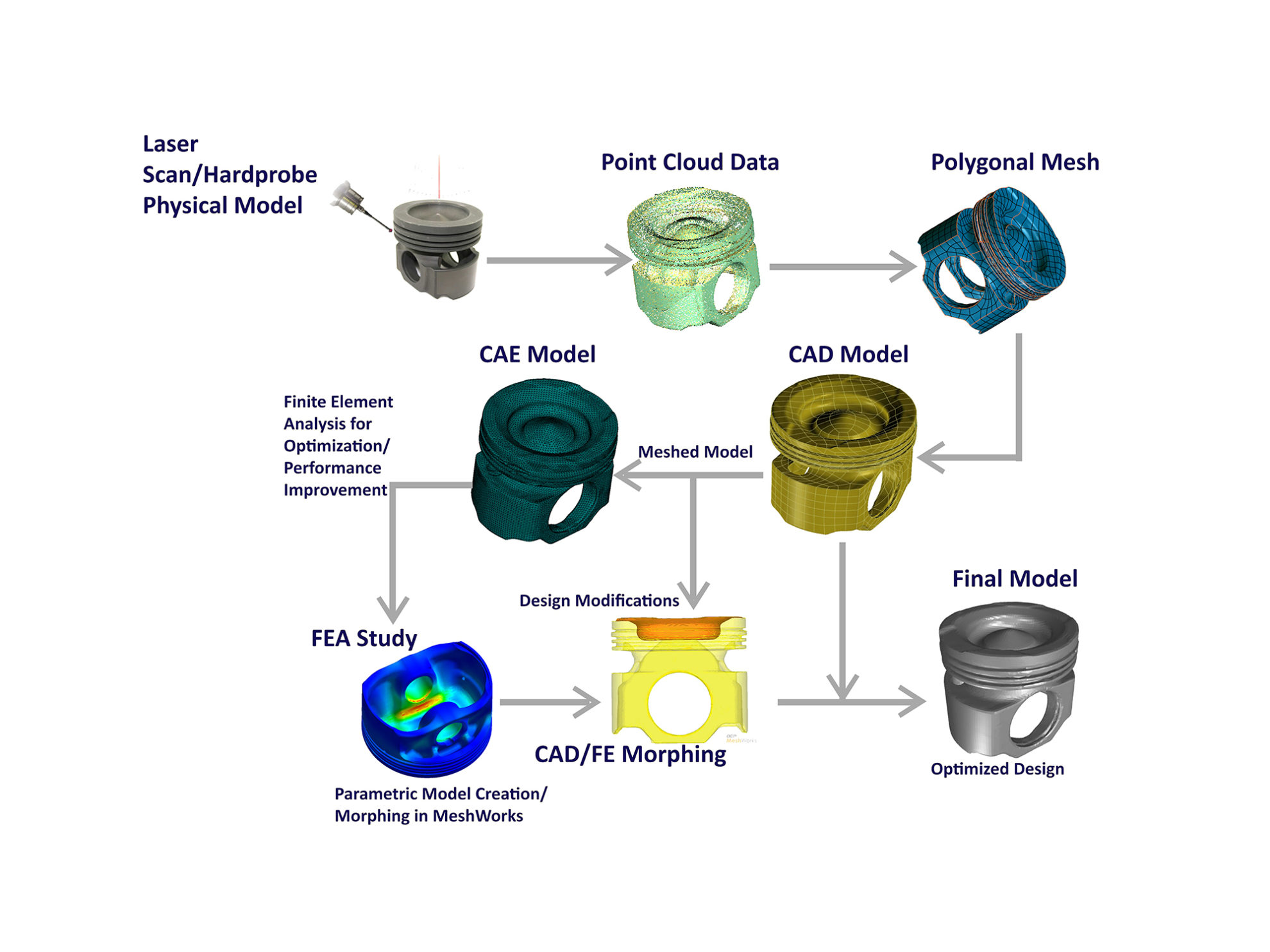

Reverse engineering is the process of taking an existing product apart and analyzing it to create a new product that is similar or identical. This can be done for a variety of reasons, such as to improve the design of an existing product, to create a new product that is compatible with an existing product, or to create a new product that is cheaper to manufacture.

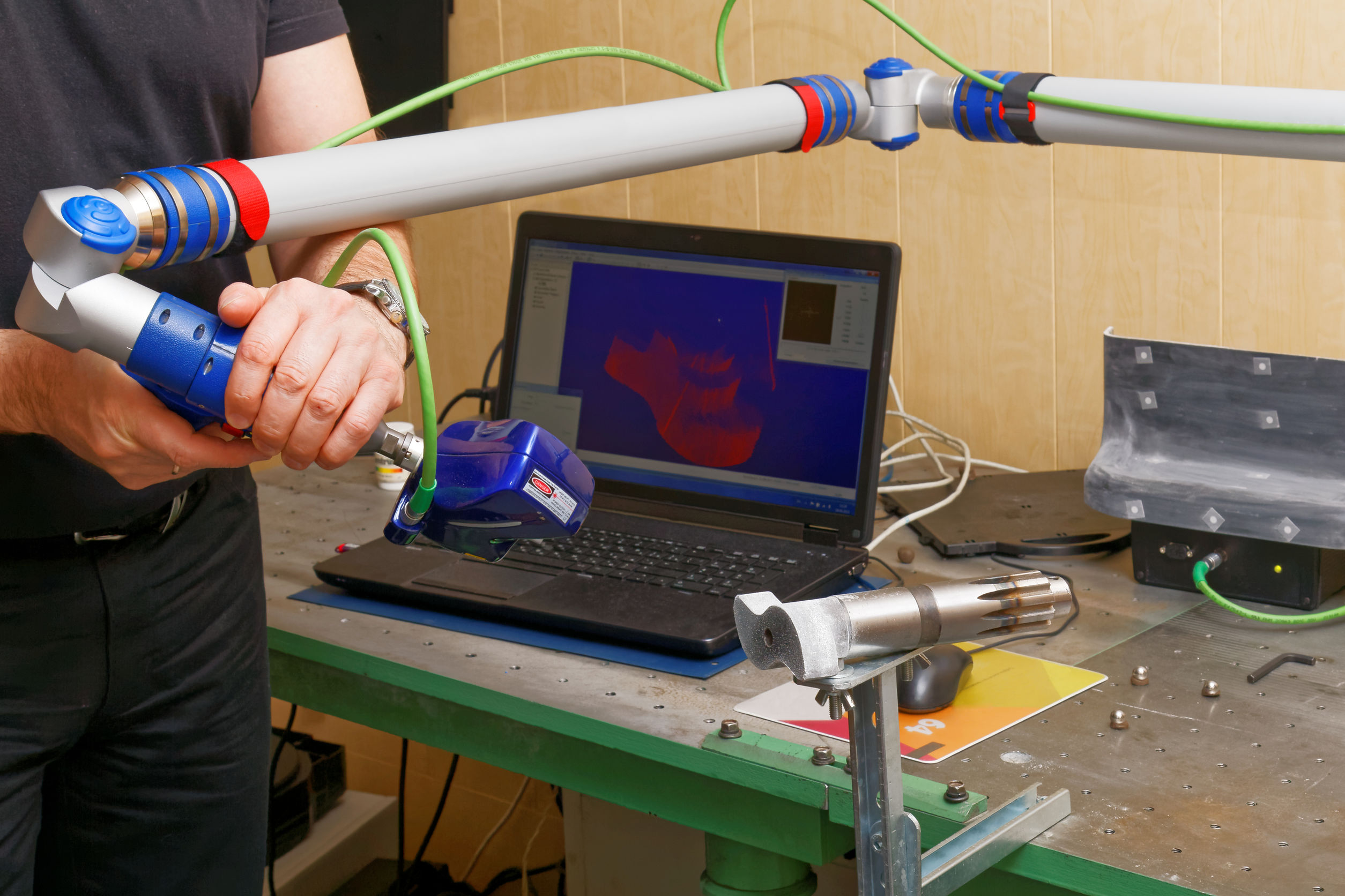

The first step in reverse engineering a product is to disassemble it. This can be done by hand or with the help of tools. Once the product is disassembled, the individual components can be analyzed. This can be done by measuring the components, examining them under a microscope, or testing them to see how they work.

Once the components have been analyzed, they can be used to create a new product. The new product can be identical to the original product, or it can be modified to improve its design or functionality.

Reverse engineering can be a valuable tool for product designers. It can help them to create new products that are of a higher quality, more compatible with existing products, and more affordable to manufacture.

Steps in Reverse Engineering Product Design

- Disassemble the product.

- Analyze the components.

- Create a new product.

- Test the new product.

Benefits of Reverse Engineering Product Design

- Can help to improve the design of an existing product.

- Can help to create a new product that is compatible with an existing product.

- Can help to create a new product that is cheaper to manufacture.