Reverse Engineering in the Medical Industry

Reverse engineering plays a critical role in the medical industry by enabling the analysis, replication, and improvement of existing medical devices and technologies. It involves disassembling a device to understand its design, materials, and functionality, with the aim of creating a similar or improved product.

Applications of Reverse Engineering in Medicine

- Product Development and Innovation: Reverse engineering allows for the study of successful medical devices and the identification of areas for improvement, leading to the development of novel and more effective solutions.

- Quality Assurance and Regulatory Compliance: Through reverse engineering, companies can verify the design and manufacturing processes of their medical devices, ensuring compliance with regulatory standards and minimizing product recalls.

- Troubleshooting and Repair: By understanding the internal workings of a device, reverse engineering helps in diagnosing malfunctions, repairing defects, and extending the lifespan of existing equipment.

- Cost Reduction and Time-to-Market Optimization: By analyzing existing devices, companies can reduce design costs, identify potential manufacturing inefficiencies, and speed up the development process.

- Educational and Research Purposes: Reverse engineering serves as a valuable educational tool for medical students and researchers, providing insights into the design principles and technical advancements of medical devices.

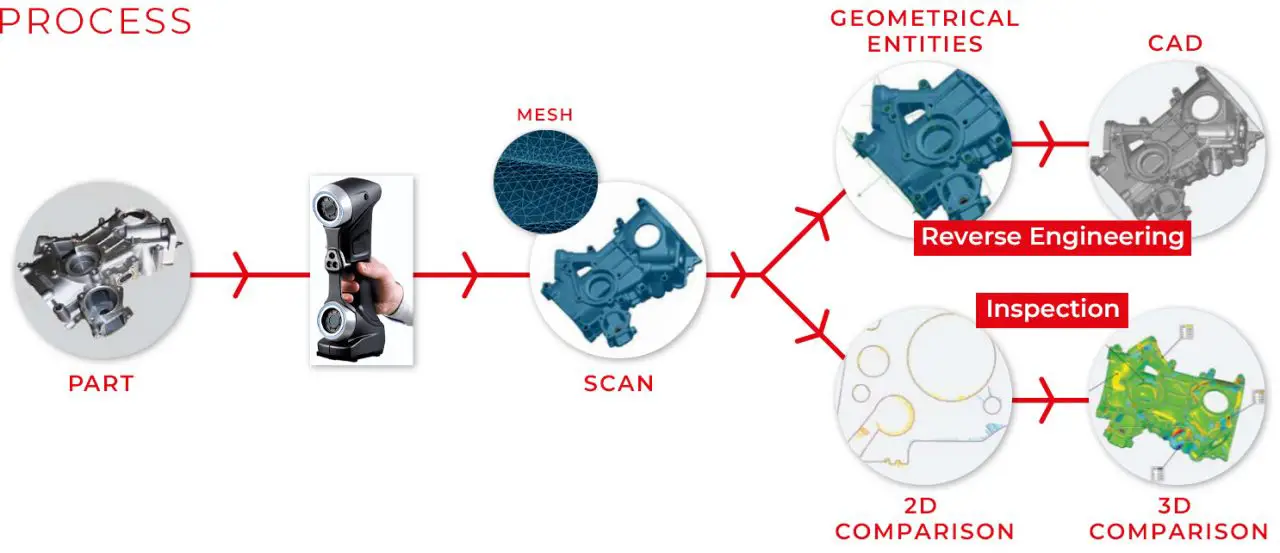

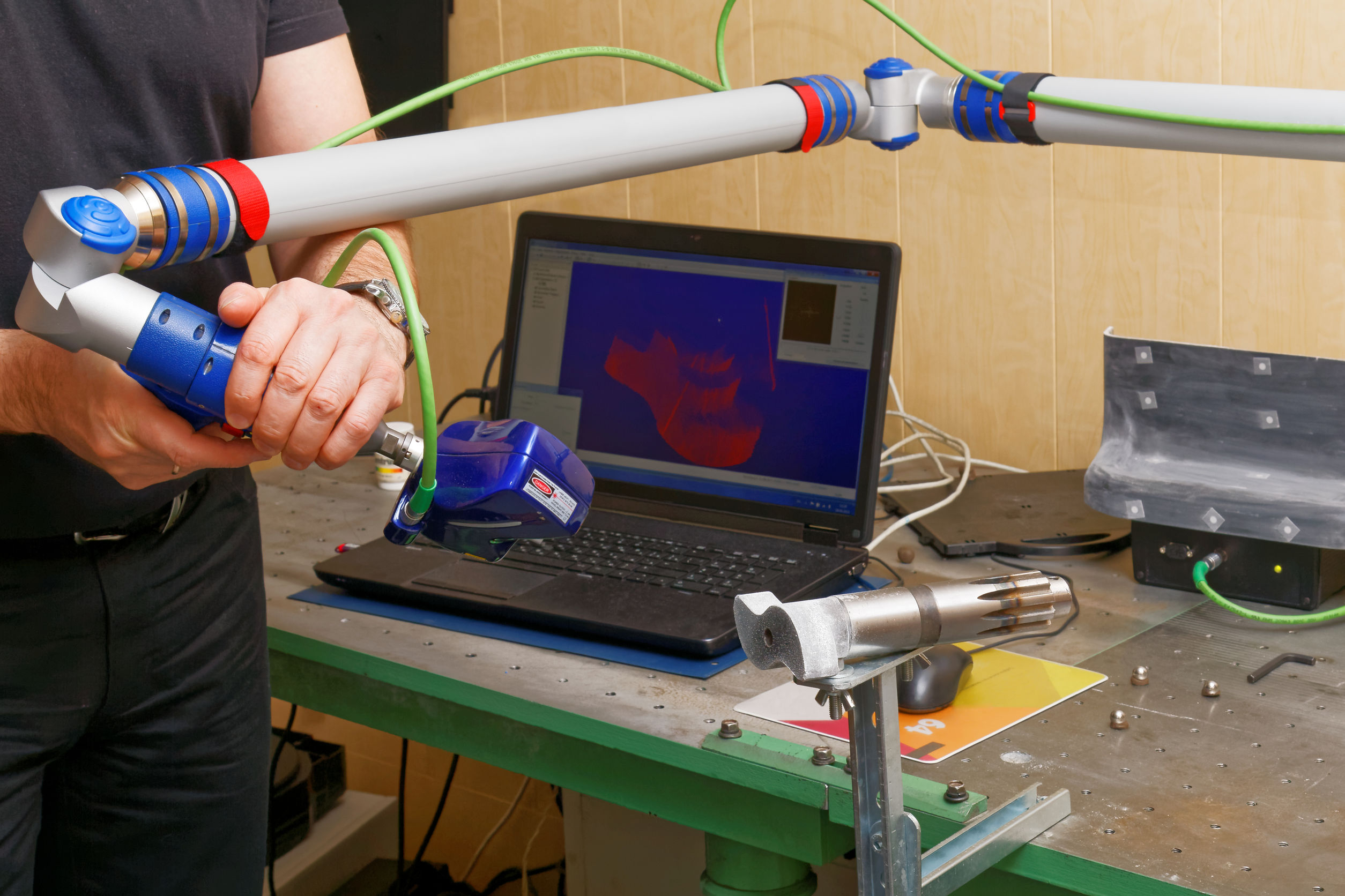

Techniques Used in Medical Reverse Engineering

- Computer-Aided Design (CAD): 3D models of the device are created using scanning techniques like computed tomography (CT) or magnetic resonance imaging (MRI).

- Materials Analysis: Chemical and physical properties of materials are determined using techniques like spectroscopy or gas chromatography.

- Functional Analysis: The device’s functionality is studied by observing its behavior under different conditions and using simulations.

- Benchmarking: The device is compared to similar products on the market to identify strengths and areas for improvement.

Benefits of Reverse Engineering in Medicine

- Improved Medical Outcomes: Enhanced medical device design and functionality lead to better patient care and treatment outcomes.

- Cost Savings: By optimizing manufacturing processes and reducing product defects, reverse engineering can save healthcare providers and patients money.

- Faster Product Development: Analysis of existing solutions accelerates innovation and time-to-market for new medical technologies.

- Greater Understanding: Reverse engineering provides invaluable insights into the design rationale and limitations of medical devices.

- Empowering Independent Manufacturers: Small and medium-sized medical technology companies can leverage reverse engineering to design and produce affordable and effective alternatives to proprietary products.