Reverse engineering is the process of taking an existing product and analyzing it to create a similar product or improve upon the original design. In the hardware industry, reverse engineering is often used to create compatible components or to develop new products that are based on existing products.

One of the most common reasons for reverse engineering in the hardware industry is to create compatible components. For example, if a company wants to create a new motherboard, they may reverse engineer an existing motherboard to ensure that their new product is compatible with the same components. This process can help to reduce the time and cost of developing new products.

Reverse engineering can also be used to develop new products that are based on existing products. For example, a company may reverse engineer a popular smartphone to create a new smartphone with similar features and functionality, but with a different design or improved performance. This process can help companies to quickly and easily create new products that are in line with consumer demand.

Reverse engineering is a powerful tool that can be used to create compatible components and develop new products in the hardware industry. By analyzing existing products, companies can save time and money, and they can also create products that are more likely to meet the needs of consumers.

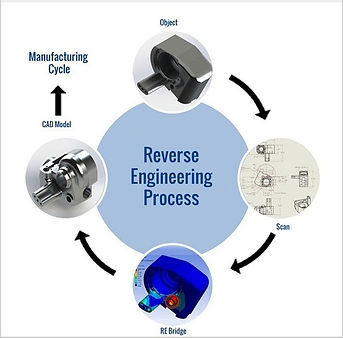

Here is a more detailed explanation of the reverse engineering process:

- Product Analysis: The first step in reverse engineering is to analyze the existing product to understand how it works. This can be done by disassembling the product, examining its components, and studying its documentation.

- Model Creation: Once the product has been analyzed, a model of the product is created. This model can be physical, such as a blueprint, or digital, such as a computer-aided design (CAD) file.

- Prototyping: Once a model has been created, a prototype of the new product can be created. This prototype is used to test the new product and to make sure that it works properly.

- Production: Once the prototype has been tested and approved, the new product can be put into production.