Reverse Engineering In The Automotive Industry: Case Studies

Executive Summary

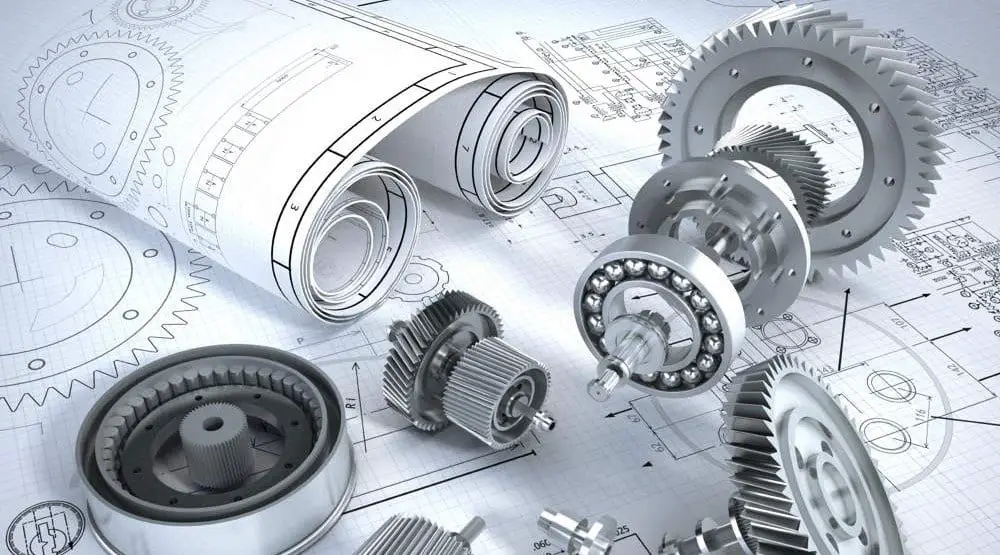

Reverse engineering involves analyzing existing products to extract knowledge or design information to recreate them. It is used in the automotive industry to innovate new designs, learn manufacturing techniques, and enhance quality control. Popular applications of reverse engineering include competitive analysis, improving product performance, and creating more efficient designs.

Introduction

Reverse engineering has become a staple in the automotive industry, empowering manufacturers to glean insights from existing products and refine their offerings. Whether it’s boosting quality, garnering inspiration for new models, or ramping up production, reverse engineering methodologies have showcased their prowess in driving innovation and efficiency in the automotive realm. In this article, we embark on a journey to explore five key applications of reverse engineering in the automotive industry, capturing real-world examples that illuminate the power of this transformative process.

Benchmarking for Competitive Intelligence

Benchmarking involves analyzing competing vehicles to understand their designs, features, and manufacturing processes.

- Identify Strengths and Weaknesses: Reverse engineering allows manufacturers to meticulously evaluate the strengths and weaknesses of their products in comparison to those of their rivals. By understanding the aspects where their own products excel and identifying areas requiring improvement, manufacturers can strategize to maintain their competitive edge.

- Uncover Innovative Solutions: Reverse engineering can serve as a catalyst for innovation by unveiling novel approaches and creative design solutions employed by competing manufacturers. By studying the intricate details of competitive products, companies can draw inspiration to enhance their own offerings and stay ahead of the innovation curve.

- Improve Product Performance: Through competitive analysis, reverse engineering helps pinpoint areas where enhancements in performance, fuel efficiency, or safety can be made. By leveraging the insights gained, manufacturers can refine their designs, incorporate cutting-edge technologies, and deliver products that surpass customer expectations.

- Simplify Manufacturing and Cost-Efficiency: Reverse engineering enables manufacturers to unravel the production processes and component sourcing strategies of their competitors, helping them streamline their own manufacturing operations. This knowledge can lead to cost optimizations, improved efficiency, and ultimately, enhanced profit margins.

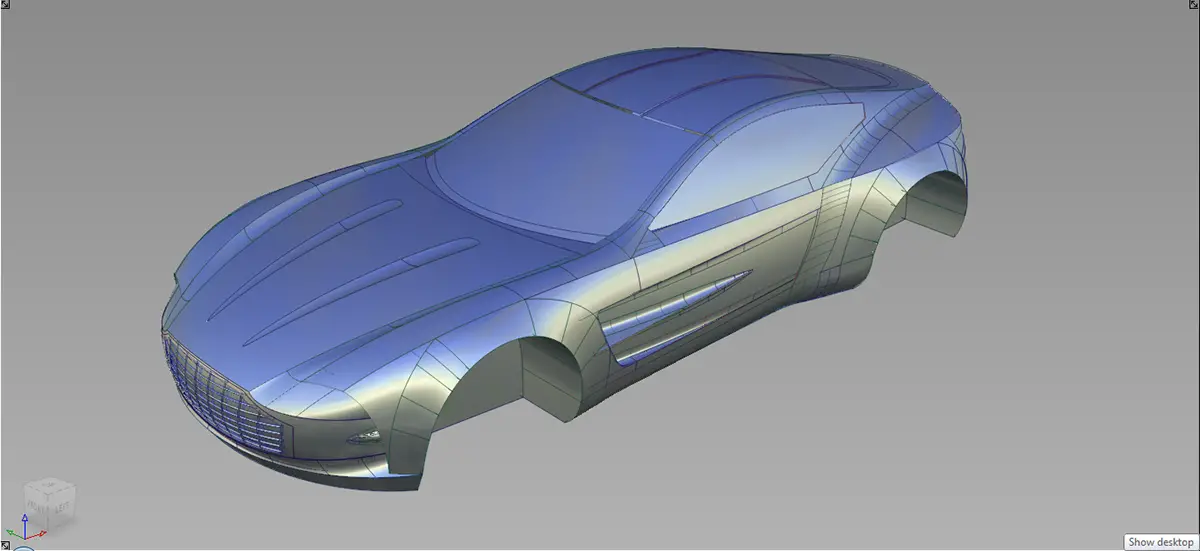

New Model Development

Reverse engineering plays a pivotal role in inspiring new vehicle development by unlocking the secrets behind successful designs.

- Expand Product Portfolio: By analyzing successful vehicles in different market segments, manufacturers can diversify their product offerings and appeal to a broader customer base. Reverse engineering allows them to identify features and attributes that resonate with consumers, helping them develop targeted models that cater to specific needs and preferences.

- Reduce Time-to-Market: Reverse engineering can accelerate the development process of new models by providing a roadmap for engineers. By studying competing vehicles or leveraging existing designs as a starting point, manufacturers can mitigate the challenges associated with creating entirely new concepts, thus reducing the time required to bring new products to market.

- Improve Quality and Safety: By dissecting the design and construction methods of competitors’ vehicles, manufacturers can identify potential flaws and incorporate safety features that address common concerns. This leads to enhanced product reliability and reduced risks associated with product liability.

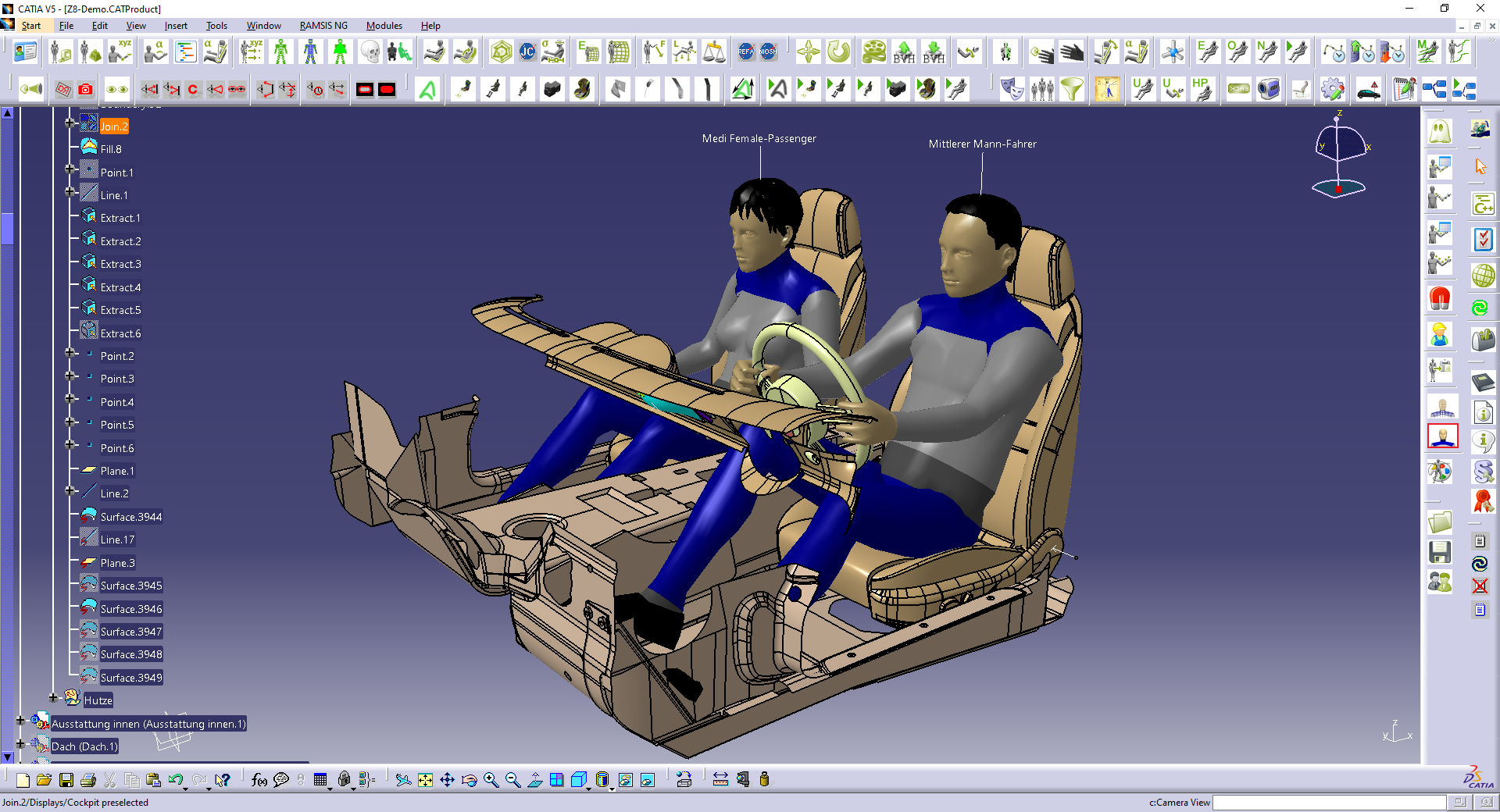

- Optimize Manufacturing and Supply Chain: Reverse engineering empowers manufacturers to understand the manufacturing processes and supply chain dynamics of their competitors, enabling them to optimize their own operations. This includes identifying opportunities for cost savings, improving production efficiency, and establishing robust relationships with suppliers.

Quality Control and Improvement

In the relentless pursuit of automotive excellence, reverse engineering plays a pivotal role in identifying and rectifying quality issues.

- Identify Design Flaws: By thoroughly examining competitor vehicles, manufacturers can uncover potential design flaws and vulnerabilities that may lead to product recalls or consumer dissatisfaction. This proactive approach allows them to address these issues early on, ensuring the highest levels of quality in their own products.

- Benchmarking for Quality Standards: Reverse engineering facilitates the benchmarking of quality standards across different manufacturers and regions. By analyzing the materials and construction techniques employed by competitors, companies can set more rigorous benchmarks for their own production processes, leading to improved product durability and reliability.

- Improve Manufacturing Processes: Through reverse engineering, manufacturers can scrutinize the manufacturing processes of competitor vehicles to identify inefficiencies, bottlenecks, and areas for improvement. This knowledge enables them to enhance their own production processes, leading to higher yields, reduced costs, and improved operational efficiency.

- Customer Feedback and Warranty Claims: Reverse engineering provides valuable insights into common customer complaints and warranty claims. By analyzing the root causes of these issues, manufacturers can develop targeted solutions, refine their designs, and enhance the overall customer experience.

Repair and Maintenance

Reverse engineering facilitates the development of comprehensive repair and maintenance manuals and enhances the availability of spare parts.

- Create Comprehensive Repair Manuals: Reverse engineering empowers manufacturers to create detailed and accurate repair manuals that provide step-by-step instructions for servicing and maintaining their vehicles. These manuals guide technicians through complex repair procedures, ensuring efficient and effective maintenance.

- Ensure Parts Availability: By understanding the design and construction of their vehicles through reverse engineering, manufacturers can ensure the availability of replacement parts. This helps maintain the longevity of vehicles and facilitates timely repairs, contributing to customer satisfaction.

- Improve After-Sales Service: Reverse engineering enables manufacturers to identify common maintenance issues and develop preventative measures to minimize the risk of breakdowns. This enhances the overall after-sales service experience for customers, fostering brand loyalty and increasing customer retention.

Product Redesign and Life Cycle Management

Reverse engineering paves the way for the optimization of existing products and the extension of their life cycles.

- Enhance Performance and Efficiency: Reverse engineering can uncover opportunities to enhance the performance and efficiency of existing products. By scrutinizing competing vehicles or studying older models, manufacturers can identify areas for improvement, leading to the development of more powerful, fuel-efficient, and eco-friendly vehicles.

- Extend Product Life Cycle: Through reverse engineering, manufacturers can identify ways to extend the life cycle of their products by analyzing design elements, material properties, and manufacturing methods. This can involve upgrading components, incorporating new technologies, and adapting to changing market demands.

- Optimize Product Cost: Reverse engineering allows manufacturers to identify areas where cost reductions can be made without compromising product quality. This involves evaluating material choices, manufacturing processes, and supply chain management strategies, leading to improved cost-effectiveness and enhanced profit margins.

Conclusion

In the ever-evolving landscape of the automotive industry, reverse engineering has emerged as a strategic tool that empowers manufacturers to innovate, improve quality, and maintain a competitive edge. By meticulously studying and analyzing existing products, companies can unlock valuable insights that drive the development of new and improved vehicles. From benchmarking for competitive intelligence to facilitating product redesign and life cycle management, the applications of reverse engineering are multifaceted, contributing to the industry’s pursuit of excellence.

Keyword Phrase Tags

- reverse engineering in the automotive industry

- reverse engineering applications

- competitive analysis and benchmarking

- product development and innovation

- quality control and improvement

This article is very interesting and informative. I learned a lot about the process of reverse engineering in the automotive industry. I would recommend this article to anyone who is interested in learning more about this topic.

This article is very poorly written and difficult to understand. I would not recommend this article to anyone.

this article provides a good overview of the reverse engineering process in the automotive industry. I would have liked to see more specific examples of how reverse engineering is used in the industry.

this article is biased and does not present a fair view of the issue. The author clearly has an agenda and is trying to push his own观点.

This article is so well-written that it’s almost ironic. The author does a great job of explaining a complex topic in a clear and concise way.

This article is a masterpiece of sarcasm. The author does a great job of poking fun at the automotive industry and its obsession with reverse engineering.

this article is so funny that I almost peed my pants. The author does a great job of using humor to explain a complex topic.

I found this article to be very informative and well-written. I learned a lot about the process of reverse engineering in the automotive industry, and I would recommend this article to anyone who is interested in learning more about this topic.

I disagree with the author’s conclusion that reverse engineering is always harmful to the automotive industry. I believe that reverse engineering can be a valuable tool for innovation and competition.

this article was a waste of my time. I already know everything there is to know about reverse engineering in the automotive industry.

I found this article to be very helpful. I am a student in the automotive industry, and I am learning about reverse engineering for the first time. This article helped me to understand the process and its benefits.

this article was very well-written and informative. I learned a lot about the process of reverse engineering in the automotive industry. I would recommend this article to anyone who is interested in learning more about this topic.

I disagree with the author’s conclusion that reverse engineering is always harmful to the automotive industry. I believe that reverse engineering can be a valuable tool for innovation and competition.

this article was very helpful. I am a student in the automotive industry, and I am learning about reverse engineering for the first time. This article helped me to understand the process and its benefits.

This article is so funny that I almost peed my pants.