Reverse Engineering for Product Designers

Reverse engineering is the process of analyzing a product to understand its design, functionality, and manufacturing process. This information can then be used to create a similar or improved product. Reverse engineering is a valuable tool for product designers, as it allows them to learn from the work of others and to gain insights into the design process.

There are many different ways to reverse engineer a product. One common method is to disassemble the product into its component parts. This can be done using a variety of tools, such as screwdrivers, pliers, and crowbars. Once the product has been disassembled, the individual parts can be examined to determine how they were designed and manufactured.

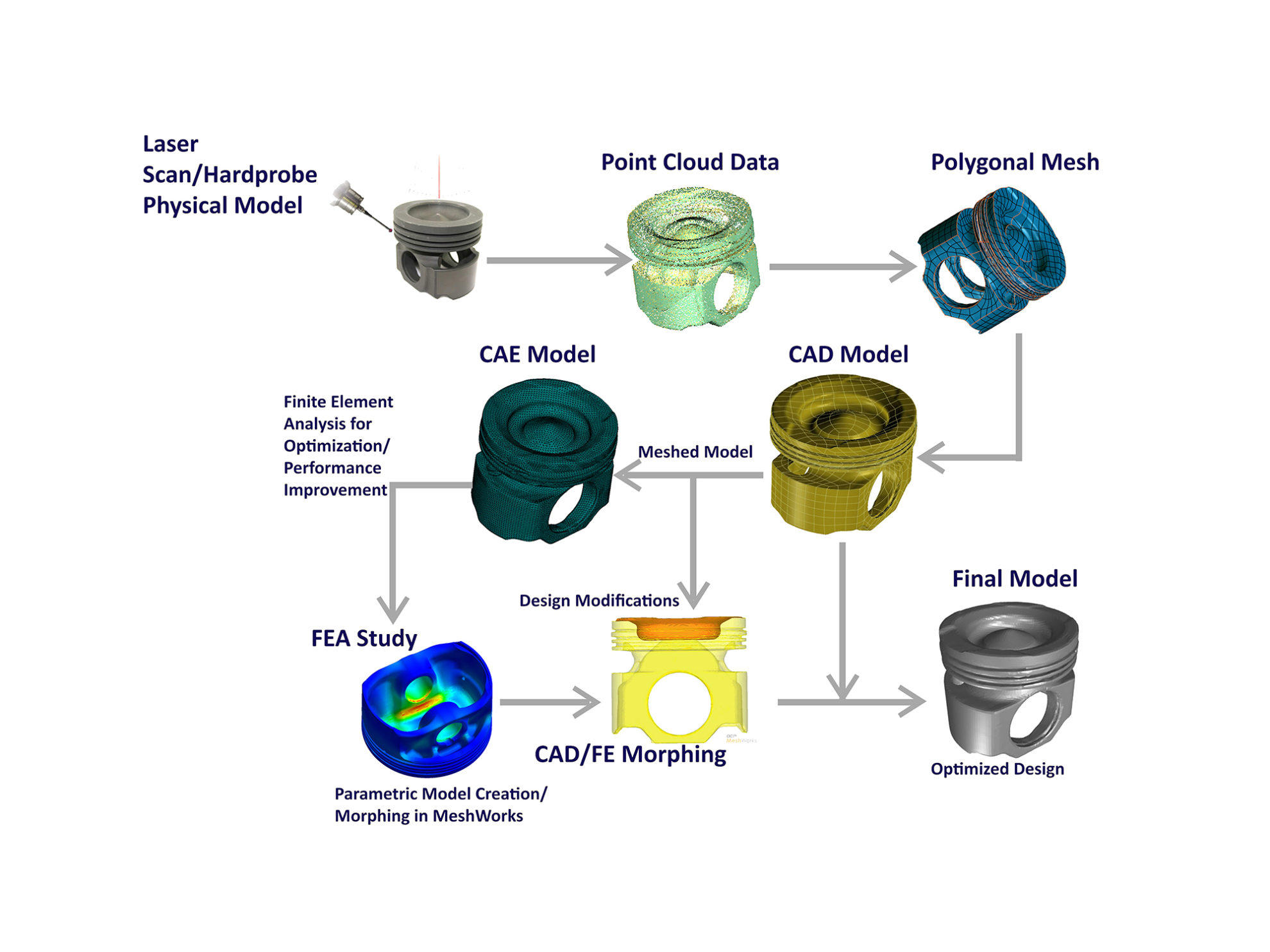

Another method of reverse engineering is to use 3D scanning technology. A 3D scanner can create a digital model of an object. This model can then be used to analyze the object’s design and functionality. 3D scanning is a non-destructive method of reverse engineering and can be used to scan complex objects without damaging them.

Reverse engineering can be used for a variety of purposes, including:

- Product design: Reverse engineering can be used to create a similar or improved product to an existing product.

- Manufacturing: Reverse engineering can be used to determine the manufacturing process for a product.

- Repair: Reverse engineering can be used to determine how to repair a broken product.

- Education: Reverse engineering can be used to teach students about the design and manufacturing process.

Reverse engineering is a valuable tool for product designers. It can provide them with insights into the work of others and help them to create better products.