Reverse Engineering for Physical Products

Reverse engineering for physical products involves the process of examining an existing product to discover its design, function, and how it was manufactured. This information can then be used to create a new product that is similar to or has improvements upon the original.

The first step in reverse engineering a physical product is to disassemble it. This can be done by carefully taking it apart, paying attention to how the different components fit together. Once the product is disassembled, it can be examined to determine how it was manufactured. This can be done by looking at the materials used, the construction methods, and the assembly process.

Once the product has been examined, it can be reassembled and tested. This will help to verify that the product was properly understood and that it functions properly. If there are any problems with the product, they can be identified and corrected before it is mass-produced.

Reverse engineering can be a valuable tool for product development. It can help to reduce the time and cost of developing new products, and it can also help to ensure that the new products are of high quality.

Here are some tips for reverse engineering physical products:

- Start with a simple product that you can easily disassemble.

- Take plenty of pictures and notes as you disassemble the product.

- Pay attention to the materials used in the product and how the different components fit together.

- Once you have disassembled the product, try to reassemble it to verify that you understood how it was put together.

- If you have any questions about the product, consult with an expert or do some research online.

- Once you have a good understanding of the product, you can begin to develop a new product that is similar to or has improvements upon it.## Reverse Engineering For Physical Products

Executive Summary

Reverse engineering for physical products is the process of taking apart a product to determine how it was made. It is an essential process for understanding how a product works, identifying areas for improvement, and developing new products. By following a step-by-step approach, manufacturers can effectively reverse engineer physical products to gain valuable insights and drive product innovation.

Introduction

Reverse engineering plays a crucial role in product development and innovation. By studying the design, materials, and manufacturing techniques used in existing products, businesses can learn from successful approaches, identify potential problems, and develop improved solutions. Reverse engineering enables companies to gain a competitive edge, innovate more effectively, and optimize their product offerings.

FAQs

Q: What are the benefits of reverse engineering physical products?

- Understand the product’s design and functionality

- Identify areas for improvement and innovation

- Improve manufacturing processes

- Reduce production costs

- Gain insights into competitor products

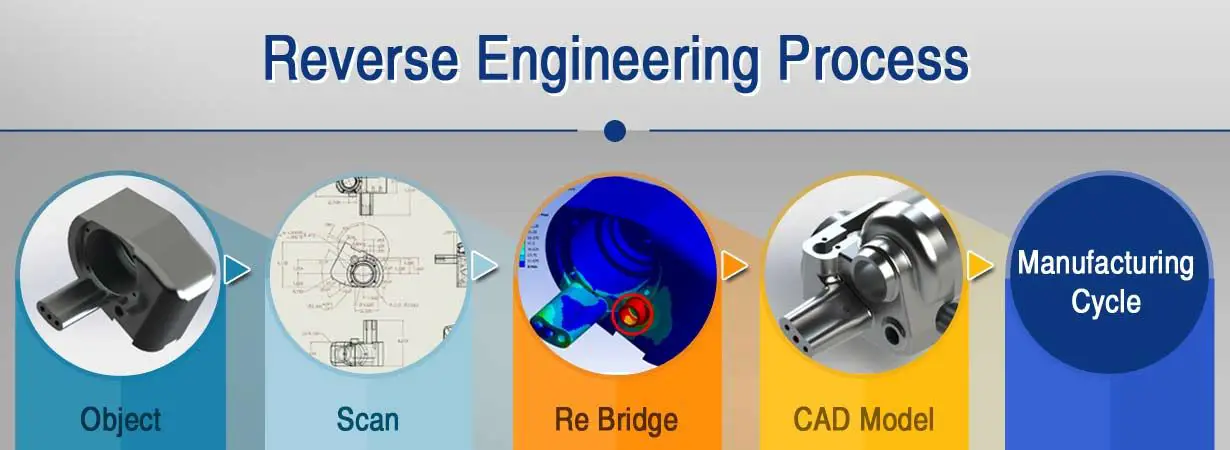

Q: What is the process of reverse engineering physical products?

- Disassemble the product: Take apart the product into its individual components.

- Analyze the components: Examine the design, materials, and manufacturing techniques used in each component.

- Document the findings: Create detailed notes, sketches, and photographs to record the product’s construction.

- Determine the product’s functionality: Test and evaluate the product to understand how it works.

- Develop insights: Analyze the findings to identify areas for improvement, innovation, and cost reduction.

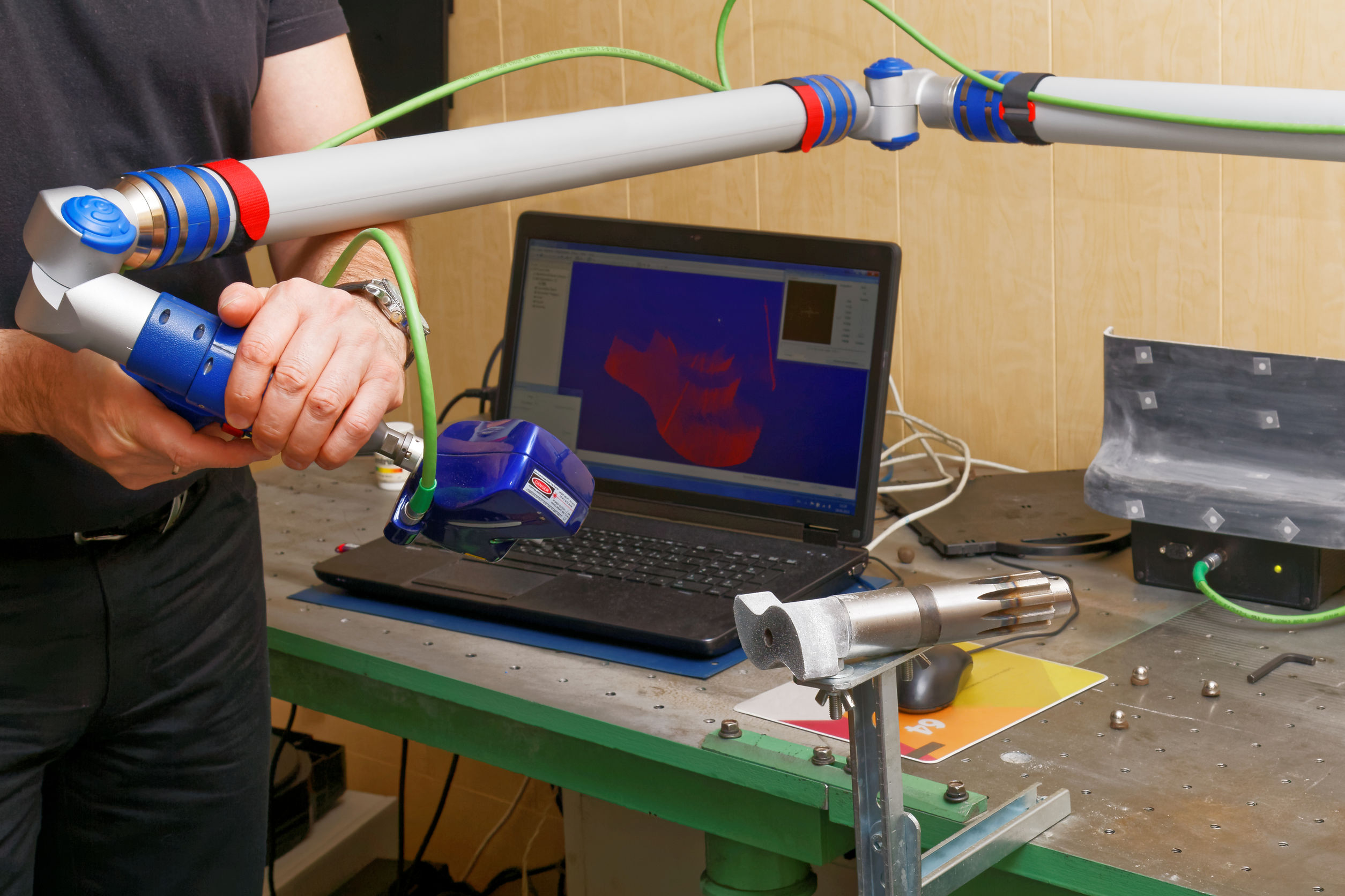

Q: What tools and resources are required for reverse engineering?

- Disassembly tools (e.g., screwdrivers, pliers)

- Measurement tools (e.g., calipers, micrometers)

- Materials analysis tools (e.g., spectrometers, microscopes)

- Computer-aided design (CAD) software

- Manufacturing process knowledge

Key Subtopics

1. Design Analysis

- Examining the product’s shape, size, and overall structure

- Assessing the materials used and their properties

- Identifying design features and functional elements

- Analyzing the principles of operation and performance

2. Materials Engineering

- Determining the composition and properties of the materials used

- Evaluating the suitability of materials for specific applications

- Identifying potential material upgrades or substitutions

- Investigating material processing techniques and their impact on performance

3. Manufacturing Processes

- Examining the steps involved in manufacturing the product

- Identifying the equipment and tools used

- Assessing the efficiency and accuracy of the manufacturing processes

- Analyzing the impact of manufacturing techniques on product quality

4. Functionality Testing

- Evaluating the product’s performance under different conditions

- Measuring key performance indicators (e.g., strength, durability, efficiency)

- Identifying potential failure points and areas for improvement

- Analyzing data to develop insights into product performance

5. Cost Optimization

- Identifying areas where production costs can be reduced

- Evaluating alternative materials and manufacturing processes

- Optimizing product design to minimize waste and assembly time

- Assessing the potential for production automation and process improvement

Conclusion

Reverse engineering physical products provides invaluable insights for businesses looking to innovate, improve, and optimize their offerings. By adopting a structured approach, manufacturers can uncover hidden strengths, identify areas for improvement, and develop new solutions that meet the evolving needs of the market. Reverse engineering empowers manufacturers to make informed decisions, stay ahead of the competition, and drive continuous product innovation.

Keyword Tags

- Reverse Engineering

- Product Development

- Physical Products

- Design Analysis

- Manufacturing