Reverse Engineering for Physical Products

Reverse engineering is the process of taking an existing product and analyzing its design and construction to create a new product that has the same or similar functionality. It can be used to create better products, improve manufacturing processes, or understand how a product works.

For physical products, reverse engineering typically involves the following steps:

- Disassembly: The product is taken apart into its component parts. This can be done manually or using automated disassembly tools.

- Inspection: Each part is inspected to determine its function, materials, and dimensions. This can be done using a variety of techniques, such as visual inspection, microscopy, and X-ray analysis.

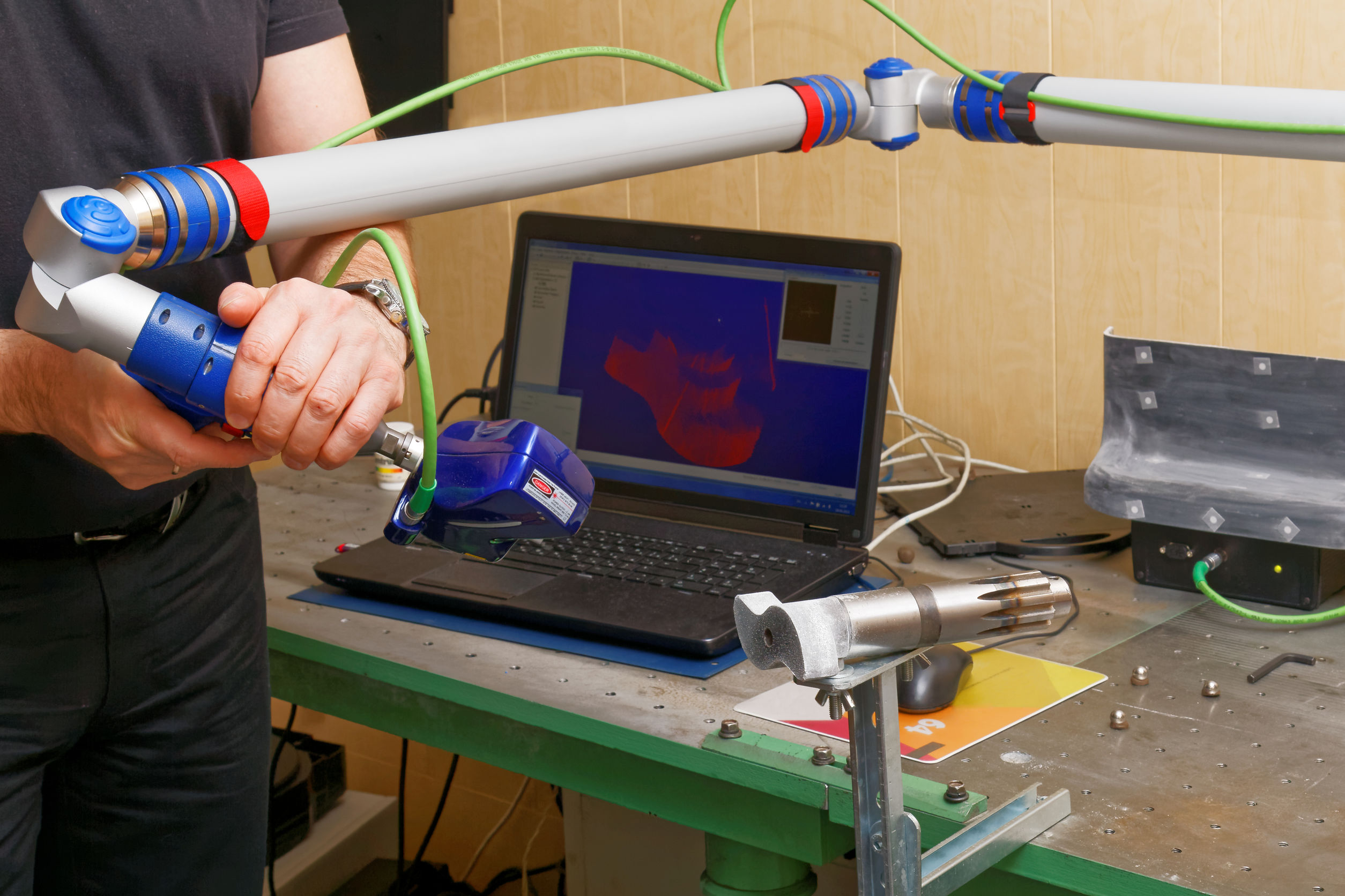

- Measurement: The dimensions and tolerances of each part are measured. This can be done using a variety of measuring tools, such as calipers, micrometers, and coordinate measuring machines.

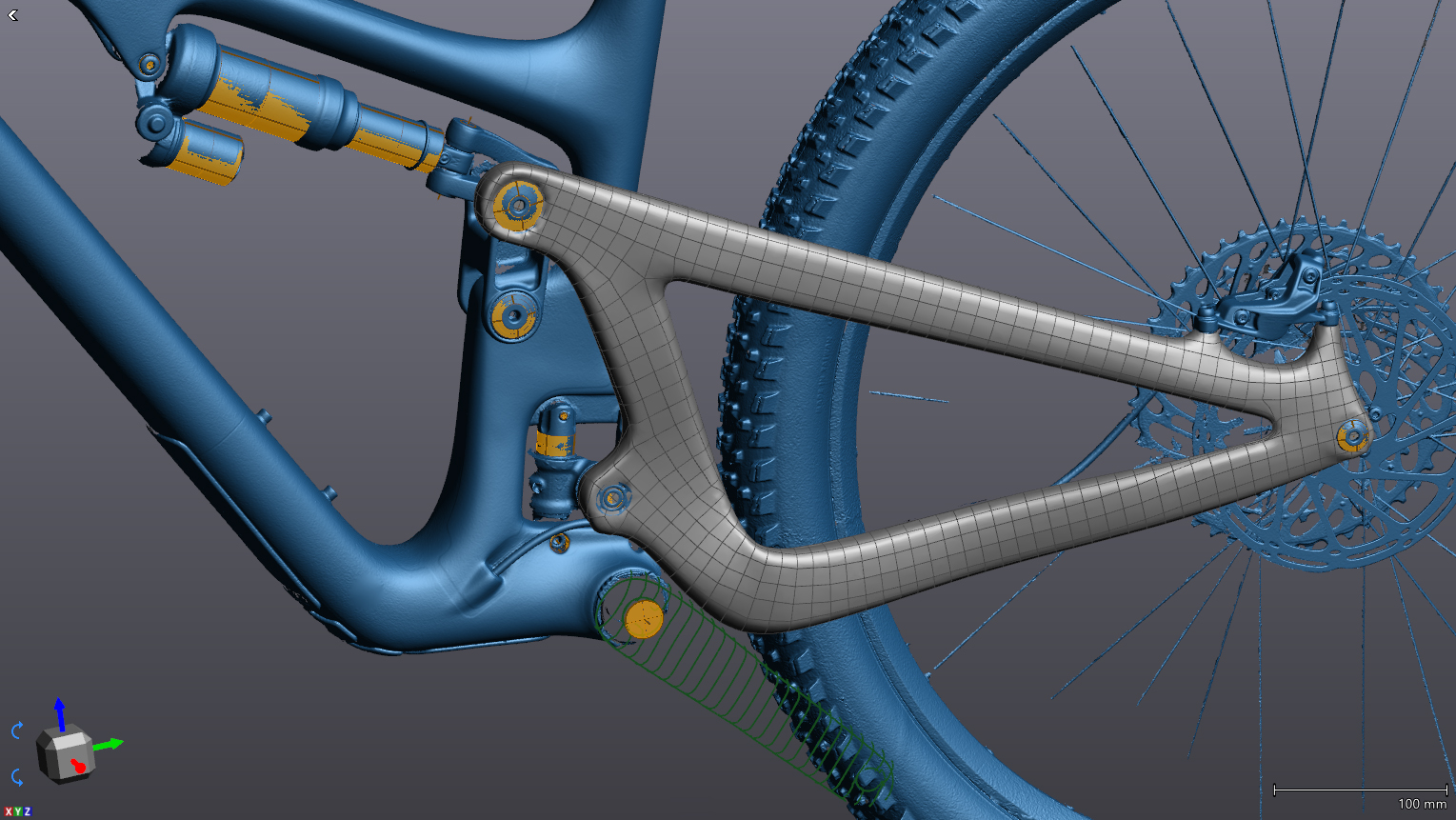

- CAD Modeling: A computer-aided design (CAD) model of the product is created based on the inspection and measurement data. This model can be used to create drawings, simulations, and other documentation.

- Analysis: The CAD model is analyzed to identify the product’s design principles, materials, and manufacturing processes. This analysis can be used to improve the product’s design or to develop new products.

Reverse engineering can be a valuable tool for a variety of purposes. It can be used to create better products, improve manufacturing processes, or understand how a product works. By following the steps outlined above, you can successfully reverse engineer a physical product.## Reverse Engineering for Physical Products

Executive Summary

Reverse engineering involves analyzing and understanding a physical product to recreate it or improve its design. This technique offers numerous benefits, including cost reduction, improved product performance, accelerated innovation, and the potential for intellectual property (IP) development.

Introduction

Reverse engineering has emerged as a valuable tool for businesses and individuals seeking to innovate and improve existing products. It empowers users to gain valuable insights into the design, functionality, and composition of target products, unlocking opportunities for enhancement and value creation.

FAQs

- What is the primary objective of reverse engineering?

To analyze and comprehend the design and function of a physical product, fostering innovation and improvements. - Who typically benefits from reverse engineering?

Businesses and individuals striving to improve existing products, develop new ones, or acquire IP rights. - What are some common applications of reverse engineering?

Analyzing competitor products, troubleshooting malfunctions, and identifying opportunities for optimization.

Top 5 Subtopics in Reverse Engineering

1. Product Disassembly

- Essential first step in reverse engineering, involving cautiously taking apart the product to understand its internal components.

- Key Considerations:

- Document all steps and observations thoroughly.

- Identify and label all components for future reference.

- Understand the sequence and method of assembly.

2. Component Identification

- Identifies and categorizes each component based on its material, size, shape, and function.

- Key Considerations:

- Determine the purpose and interaction of each component.

- Analyze the material composition for durability and performance.

- Identify potential performance limitations or improvement areas.

3. Dimensional Analysis

- Measures and documents the dimensions of all critical components to create accurate mechanical drawings.

- Key Considerations:

- Use precision measuring tools for precise measurements.

- Create dimensioned sketches or 3D models for documentation.

- Consider tolerances and allowances for manufacturing purposes.

4. Functional Analysis

- Evaluates the product’s functional capabilities and performance through testing and observation.

- Key Considerations:

- Perform user testing to observe the product in action.

- Test different use cases and operating conditions.

- Analyze data to identify potential performance bottlenecks.

5. Materials Analysis

- Determines the composition and properties of materials used in the product.

- Key Considerations:

- Utilize microscopy and spectroscopy to identify materials.

- Analyze material properties such as strength, hardness, and durability.

- Identify potential cost reduction opportunities through material substitution.

Conclusion

Reverse engineering empowers businesses and individuals to innovate, improve, and enhance physical products. By understanding a target product’s design, functionality, and materials, users can uncover opportunities for cost reduction, performance optimization, and IP development. The structured process outlined in this article provides a comprehensive approach to successful reverse engineering initiatives.

Relevant Keyword Tags

- Reverse Engineering

- Product Innovation

- Manufacturing

- Design Optimization

- Intellectual Property