Reverse Engineering for Medical Products

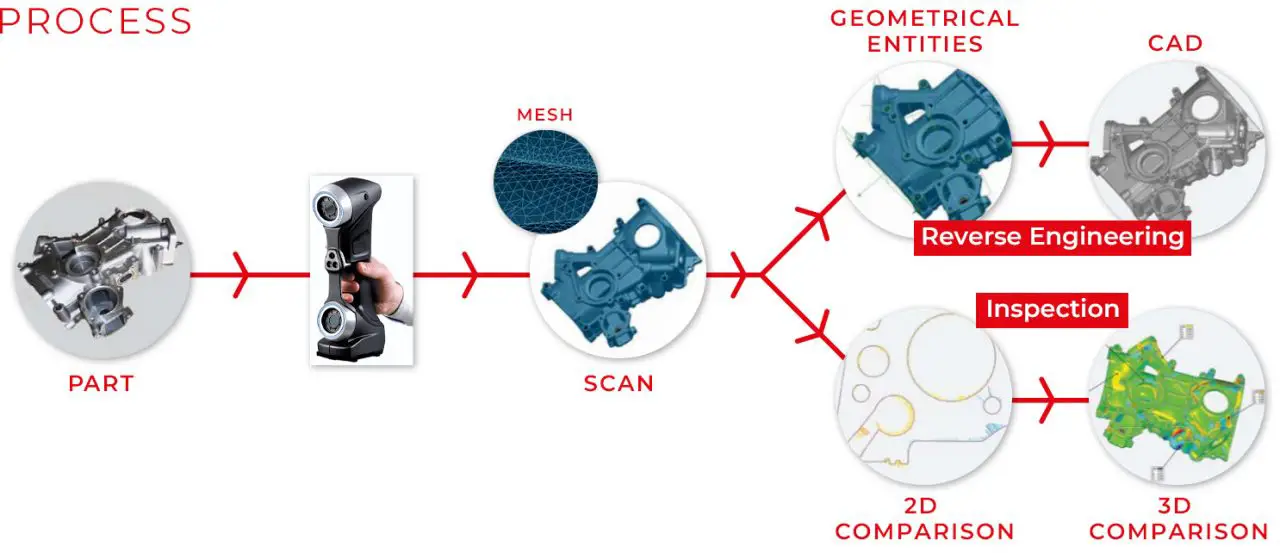

Reverse engineering involves disassembling or dismantling a product to gain an understanding of its design, function, and components. In the medical device industry, reverse engineering plays a critical role in various aspects:

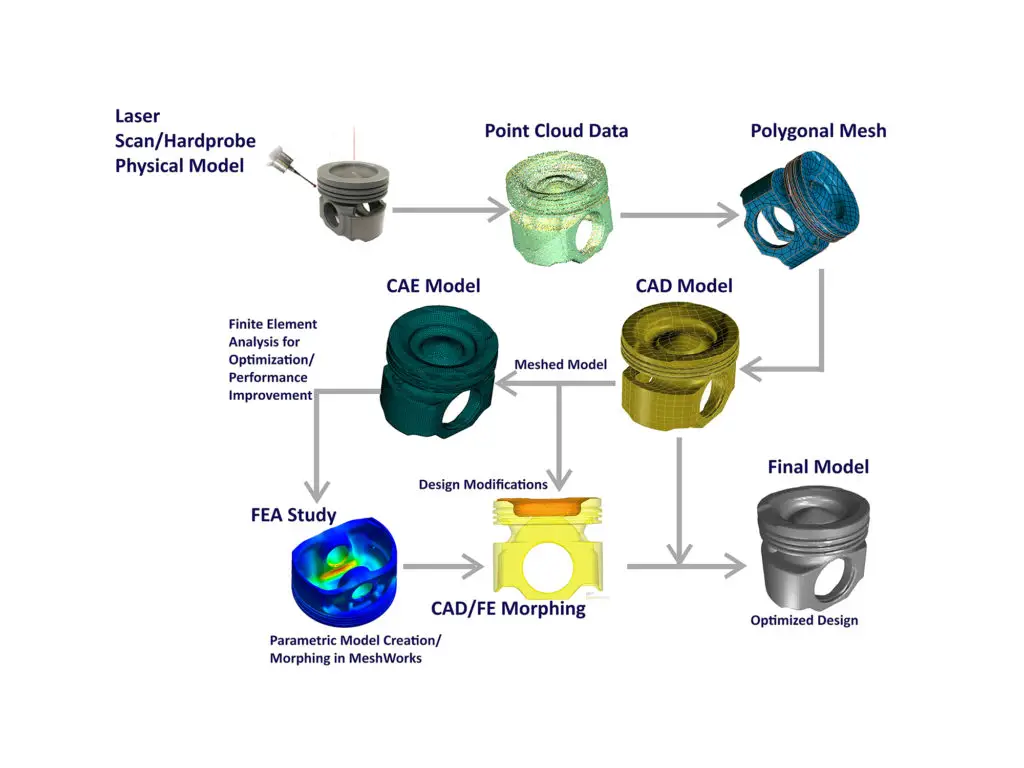

Product Development and Improvement: By analyzing existing medical devices, manufacturers can identify potential areas for improvement, such as enhancing performance, reducing costs, or addressing safety concerns. Reverse engineering can provide insights into the design principles, materials, and manufacturing techniques used, allowing for the development of more effective and efficient medical products.

Quality Control and Troubleshooting: Reverse engineering can help identify defects or areas of concern in medical devices. By comparing the actual product to the original design specifications, manufacturers can pinpoint manufacturing errors, material failures, or design flaws. This information can be used to improve quality control processes and resolve any issues related to the device’s performance or safety.

Cost Reduction and Material Selection: Reverse engineering can provide valuable data on the materials and manufacturing techniques used in existing medical devices. This information can be leveraged to identify cost-effective alternatives, optimize material selection, and streamline manufacturing processes.

Compliance and Regulatory Approval: Medical device manufacturers must comply with stringent regulatory requirements. Reverse engineering can help ensure compliance by verifying that the device meets design specifications, manufacturing standards, and safety regulations. It can also provide evidence of the device’s safety and efficacy during the regulatory approval process.

Patent Infringement Avoidance: Before launching a new medical device, it is essential to conduct a thorough patent search to avoid infringement of existing patents. Reverse engineering can help manufacturers assess the originality and patentability of their design by identifying similar technologies and their protected aspects.

Competitive Analysis and Market Research: Reverse engineering can provide insights into the competitive landscape of the medical device industry. By studying the design and features of competitor’s products, manufacturers can understand their strengths and weaknesses, identify market trends, and make informed decisions regarding product positioning and marketing strategies.