Reverse Engineering For Innovation

Executive Summary:

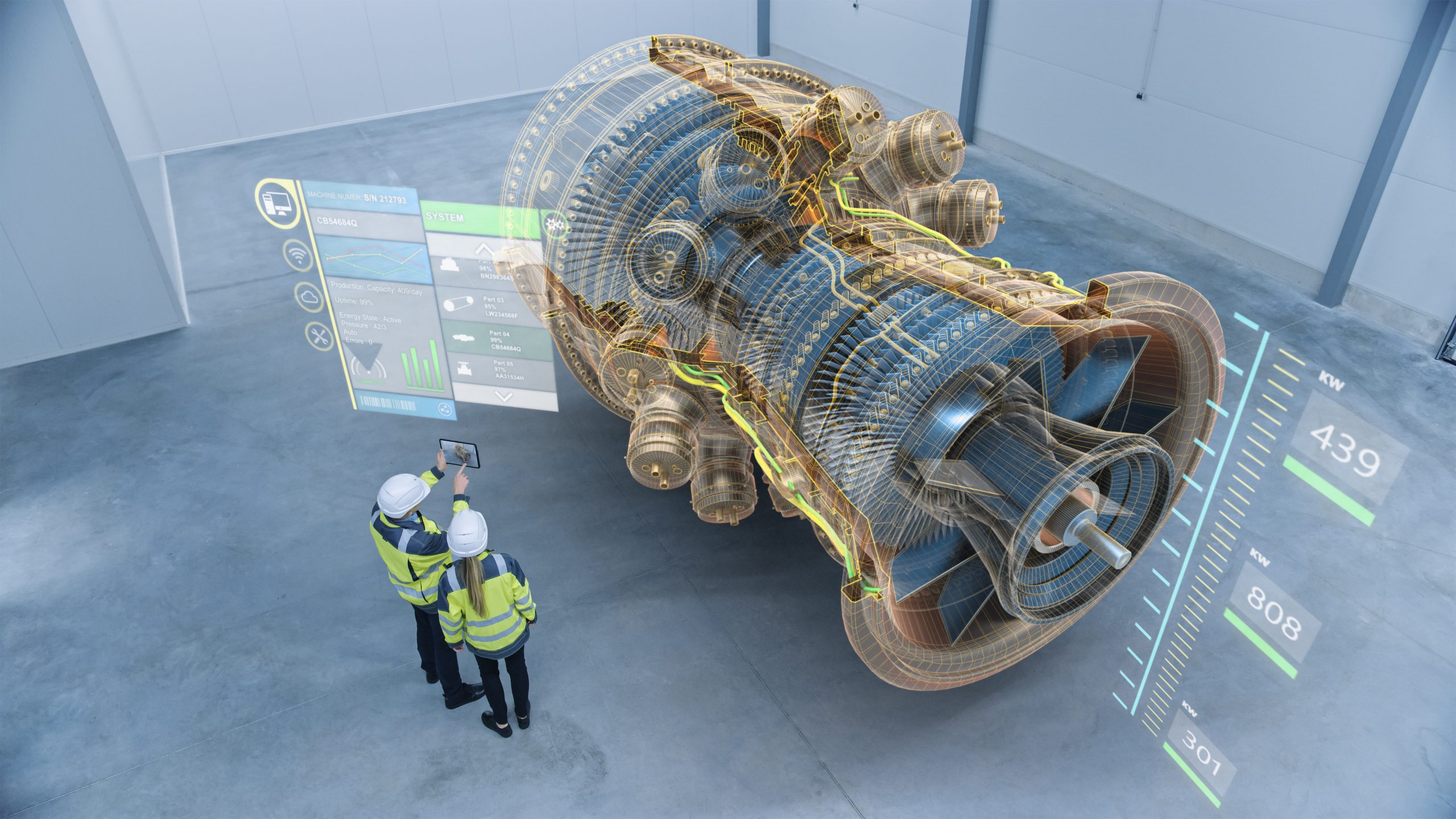

Reverse engineering is the process of studying a product to understand its construction and functionality. It can be used for a variety of purposes, including innovation, cost reduction, and quality improvement. Companies that are able to master reverse engineering can gain a significant competitive advantage.

Introduction:

In today’s competitive business environment, companies are constantly looking for new ways to innovate and improve their products. Reverse engineering is a powerful tool that can help companies achieve these goals. By studying existing products, companies can learn about the latest technologies and trends, and they can identify areas where they can improve their own products.

FAQ:

Q: What are the benefits of reverse engineering?

A: Reverse engineering can provide a number of benefits, including:

- Reduced costs: By understanding the construction of a product, companies can often find ways to reduce their own production costs.

- Improved quality: By studying the design of a product, companies can identify areas where they can improve the quality of their own products.

- Increased innovation: Reverse engineering can help companies identify new technologies and trends, which can lead to new product ideas.

Q: What are the challenges of reverse engineering?

A: Reverse engineering can be a challenging process, especially for complex products. Some of the challenges include:

- Obtaining the product: In order to reverse engineer a product, companies must first obtain a copy of the product. This can be difficult, especially for products that are not available commercially.

- Disassembling the product: Once a company has a copy of a product, it must disassemble the product in order to study its construction. This can be a time-consuming and complex process, especially for products that are held together with glue or other adhesives.

- Understanding the design: Once a company has disassembled a product, it must understand the design of the product. This can be difficult, especially for products that are designed using complex software.

Q: What are the legal implications of reverse engineering?

A: The legal implications of reverse engineering vary from country to country. In the United States, reverse engineering is generally legal, but there are some restrictions. For example, it is illegal to reverse engineer a product if it is protected by a patent.

Top 5 Subtopics:

1. Disassembly:

Disassembly is the process of taking a product apart in order to study its construction. This can be a time-consuming and complex process, especially for products that are held together with glue or other adhesives.

- Tools for disassembly: The tools used for disassembly will vary depending on the product. Some of the most common tools include screwdrivers, pliers, and hammers.

- Safety precautions: It is important to take safety precautions when disassembling a product. Some products may contain dangerous chemicals or components. Always wear appropriate safety gear, such as gloves and safety glasses.

- Documentation: It is important to document the disassembly process. This will help you to reassemble the product later, and it will also provide a valuable record of the product’s construction.

2. Analysis:

Analysis is the process of studying the construction and functionality of a product. This can be done through a variety of methods, including visual inspection, microscopy, and X-ray analysis.

- Visual inspection: Visual inspection is the most basic form of analysis. This involves simply looking at the product and identifying its components and construction.

- Microscopy: Microscopy is a technique that uses a microscope to magnify the product and its components. This can help to identify small details and defects that are not visible to the naked eye.

- X-ray analysis: X-ray analysis is a technique that uses X-rays to create an image of the product’s internal structure. This can help to identify hidden defects and components that are not visible through other methods.

3. Reconstruction:

Reconstruction is the process of reassembling a product after it has been disassembled. This can be a challenging process, especially for complex products.

- Assembly instructions: If available, assembly instructions can be a valuable resource when reassembling a product.

- Patience: Reassembling a product can be a time-consuming process. It is important to be patient and to carefully follow the instructions.

- Testing: Once the product has been reassembled, it is important to test it to make sure that it is functioning properly.

4. Evaluation:

Evaluation is the process of assessing the quality and performance of a product. This can be done through a variety of methods, including testing, inspection, and comparison.

- Testing: Testing is the most direct way to evaluate the quality and performance of a product. This involves testing the product under a variety of conditions to see how it performs.

- Inspection: Inspection is another way to evaluate the quality and performance of a product. This involves examining the product for defects and other problems.

- Comparison: Comparison is a good way to evaluate the quality and performance of a product relative to other products. This involves comparing the product to similar products in terms of features, performance, and cost.

5. Improvement:

Improvement is the process of making changes to a product to improve its quality and performance. This can be done through a variety of methods, including redesign, new materials, and new processes.

- Redesign: Redesign is the process of making changes to the design of a product. This can be done to improve the product’s functionality, performance, or aesthetics.

- New materials: Using new materials can improve the quality and performance of a product. For example, using a stronger material can make the product more durable.

- New processes: Using new processes can improve the efficiency and cost-effectiveness of producing a product. For example, using a new manufacturing process can reduce the cost of producing the product.

Conclusion:

Reverse engineering is a powerful tool that can help companies innovate and improve their products. By studying existing products, companies can learn about the latest technologies and trends, and they can identify areas where they can improve their own products. Companies that are able to master reverse engineering can gain a significant competitive advantage.

Keyword Tags:

- Reverse engineering

- Innovation

- Product design

- Quality improvement

- Cost reduction