Reverse Engineering for Hardware Developers

Executive Summary

Reverse engineering is a valuable technique for hardware developers to gain insights into the design and functionality of existing devices. By breaking down a device into its component parts and analyzing its circuitry, developers can uncover valuable knowledge that can be applied to their own projects. This comprehensive guide provides a detailed overview of reverse engineering for hardware developers, covering key concepts, techniques, and industry best practices.

Introduction

Reverse engineering is the process of taking an existing device or product apart and analyzing its design and function. This process can be used to gain insights into how the device works, to identify potential improvements, or to create a new product that is similar to the original. In the field of hardware development, reverse engineering can be a valuable tool for understanding the design choices and manufacturing processes of competitor’s products. By reverse engineering a device, developers can learn about the latest technologies, identify potential design flaws, and develop new ideas for their own products.

FAQs

Q: What are the benefits of reverse engineering?

A: Reverse engineering offers several benefits, including:

- Gaining insights into how a device works

- Identifying potential improvements

- Creating a new product that is similar to the original

Q: What tools are needed for reverse engineering hardware?

A: The tools needed for reverse engineering hardware can vary, but commonly include:

- A microscope

- A soldering iron

- A multimeter

- A logic analyzer

- Software for schematics and PCB layout

Q: What are the ethical considerations of reverse engineering?

A: Reverse engineering is generally legal in most countries, but it is important to be aware of any copyright or patent protection that may apply to the device being reverse engineered.

Subtopics

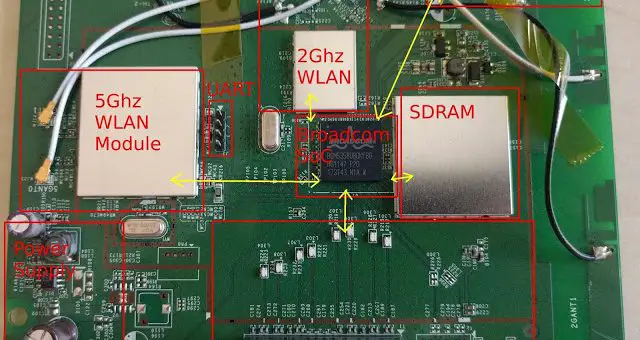

1. Design Analysis

Design analysis involves examining the physical layout and construction of a device to understand its overall design and function.

- Component identification: Identifying the individual components used in the device, including ICs, resistors, capacitors, and transistors.

- PCB layout: Analyzing the layout of the printed circuit board (PCB) to determine the connectivity between components.

- Signal tracing: Tracing the flow of signals through the device to understand how the components interact.

2. Circuit Analysis

Circuit analysis involves studying the electrical circuits within a device to determine their functionality and design principles.

- Schematic capture: Creating a schematic diagram of the device’s circuits to visualize the flow of current and voltage.

- Functional analysis: Analyzing the function of each circuit block to understand how the device performs its intended task.

- Simulation: Using simulation tools to model the behavior of the circuits and validate the design.

3. Firmware Analysis

Firmware analysis involves examining the embedded software that controls the device’s operation.

- Code extraction: Extracting the firmware from the device’s memory using specialized tools.

- Disassembly: Converting the firmware into a human-readable format to understand its functionality and structure.

- Functional analysis: Analyzing the firmware code to determine its function, identify potential vulnerabilities, and modify its behavior.

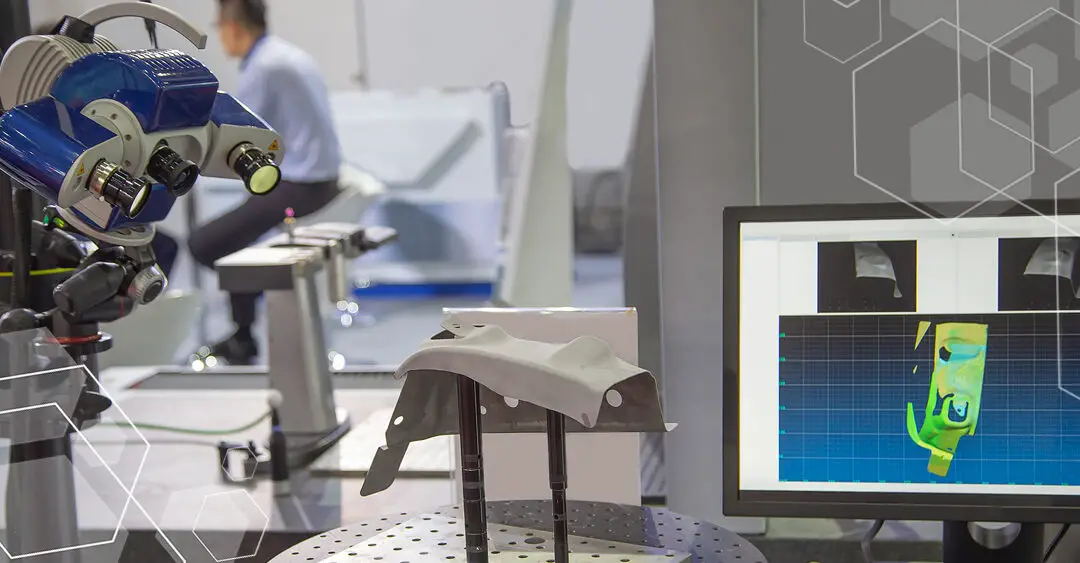

4. Mechanical Analysis

Mechanical analysis involves examining the physical structure and materials used in a device to understand its mechanical design and performance.

- Materials analysis: Identifying the materials used in the device and studying their properties to understand their suitability and performance.

- Structural analysis: Analyzing the structural design of the device to determine its strength, durability, and resistance to environmental factors.

- Failure analysis: Identifying potential failure modes and analyzing the causes of device failure to improve its reliability.

5. Data Analysis

Data analysis involves examining the data generated by a device to understand its usage patterns and performance metrics.

- Data acquisition: Collecting data from the device using sensors or other tools to monitor its operation.

- Data analysis: Analyzing the collected data to identify trends, patterns, and anomalies to improve the design and functionality of the device.

- Predictive analytics: Using data analysis techniques to predict future behavior and performance of the device to optimize its usage and maintenance.

Conclusion

Reverse engineering is a powerful technique that can provide valuable insights into the design and functionality of hardware devices. By carefully following the steps outlined in this guide, hardware developers can learn about the latest technologies, identify potential improvements, and develop new ideas for their own products. Understanding the subfields of reverse engineering, including design analysis, circuit analysis, firmware analysis, mechanical analysis, and data analysis, empowers developers to thoroughly examine devices and uncover valuable information that can drive innovation and success.