Reverse Engineering for Electronics Products

Executive Summary

Reverse engineering is the process of taking a product apart to understand how it works. This can be done for a variety of reasons, such as to repair a product, to improve a product, or to create a new product. Reverse engineering can be a complex and time-consuming process, but it can also be very rewarding.

Introduction

Reverse engineering is not just about taking a product apart. It is also about understanding how the product works. This can be done by examining the product’s design, its materials, and its manufacturing process. Reverse engineering can also involve testing the product to see how it performs.

Why Reverse Engineer?

- There are many reasons why someone might want to reverse engineer an electronics product. Some of the most common reasons include:

- To repair a product. Reverse engineering can help you to understand how a product works so that you can repair it yourself.

- To improve a product. Reverse engineering can help you to find ways to improve the performance or functionality of a product.

- To create a new product. Reverse engineering can help you to create a new product that is based on an existing product.

How to Reverse Engineer

Reverse engineering can be a complex process, but it can be broken down into a few basic steps:

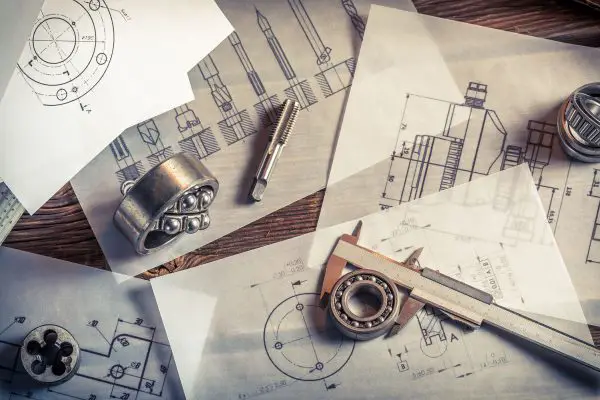

- Document the product. The first step is to document the product. This includes taking pictures of the product, measuring its dimensions, and recording any other relevant information.

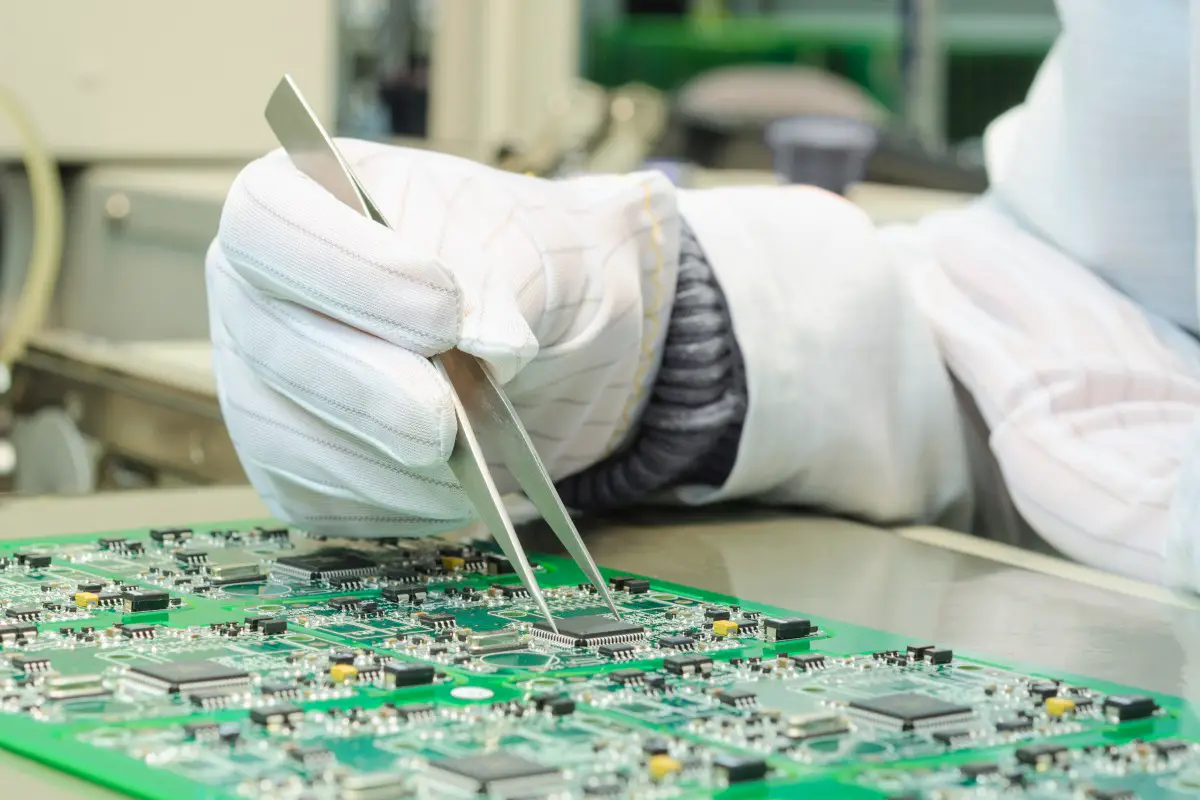

- Take the product apart. The next step is to take the product apart. This should be done carefully so that you do not damage any of the components.

- Examine the components. Once you have taken the product apart, you should examine the components. This includes looking at the design of the components, the materials used, and the manufacturing process.

- Test the components. You may also want to test the components to see how they perform. This can help you to understand how the product works.

- Reassemble the product. Once you have examined the components, you can reassemble the product. This should be done carefully so that the product is not damaged.

FAQs

1. What are the benefits of reverse engineering?

Answer: Reverse engineering can provide several benefits, including:

- It can help you understand how a product works.

- It can help you to repair a product.

- It can help you to improve a product.

- It can help you to create a new product.

2. What are the challenges of reverse engineering?

Answer: Reverse engineering can be a challenging process, due to:

- The complexity of some products.

- The need for specialized knowledge and equipment.

- The time and effort required.

3. What tools are needed for reverse engineering?

Answer: The tools needed for reverse engineering vary depending on the product being reverse engineered. However, some common tools include:

- Screwdrivers

- Pliers

- Multimeters

- Oscilloscopes

- Software for documentation and analysis

Top 5 Subtopics of Reverse Engineering

1. Understanding the Product

Reverse engineering begins with understanding the product. This can be done by studying the product’s documentation, examining its design, and taking it apart.

Important Pieces:

- Product documentation: This includes manuals, schematics, and other documents that can provide information about the product’s design and function.

- Product design: This includes the physical structure of the product, the materials used, and the manufacturing process.

- Product function: This includes the purpose of the product and how it works.

2. Identifying the Components

Once the product is understood, the next step in reverse engineering is to identify the components of the product. This can be done by visually inspecting the product, using documentation, or using testing equipment.

Important Pieces:

- Component identification: This is the process of determining the type of component used in the product.

- Component function: This is the process of determining the purpose of the component in the product.

- Component replacement: This is the process of determining how to replace a component in the product.

3. Analyzing the Circuitry

For electronic products, reverse engineering often involves analyzing the circuitry of the product. This can be done by using a schematic diagram, a multimeter, or an oscilloscope.

Important Pieces:

- Circuit analysis: This is the process of understanding how the circuitry of the product works.

- Component interactions: This is the process of understanding how the components in the circuitry interact with each other.

- Circuit modifications: This is the process of determining how to modify the circuitry of the product.

4. Testing the Product

Once the product is understood, the next step in reverse engineering is to test the product. This can be done by using a multimeter, an oscilloscope, or other testing equipment.

Important Pieces:

- Functional testing: This is the process of testing the product to see if it works as intended.

- Performance testing: This is the process of testing the product to see how it performs in different conditions.

- Stress testing: This is the process of testing the product to see how it withstands extreme conditions.

5. Documenting the Results

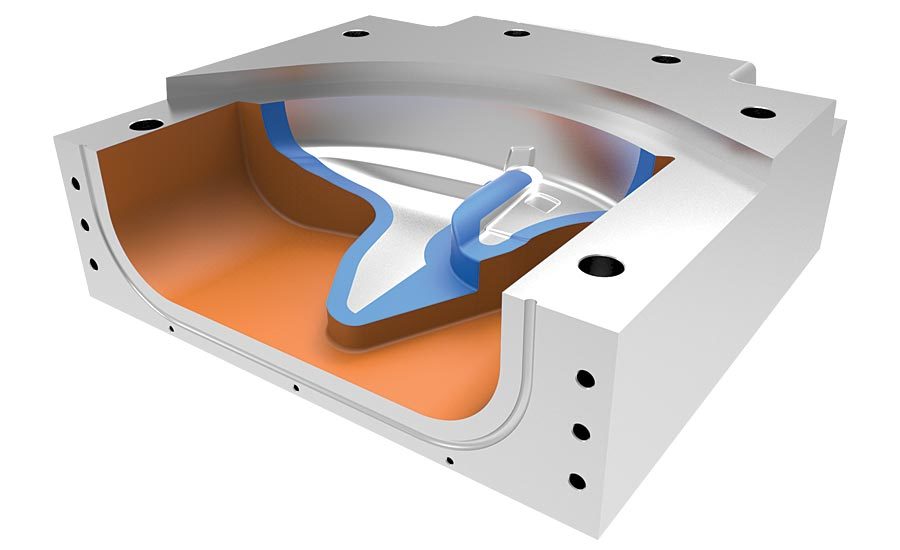

The final step in reverse engineering is to document the results. This can be done by writing a report, creating a schematic diagram, or creating a 3D model.

Important Pieces:

- Report writing: This is the process of documenting the results of the reverse engineering process.

- Schematic creation: This is the process of creating a diagram of the circuitry of the product.

- 3D modeling: This is the process of creating a 3D model of the product.

Conclusion

Reverse engineering is a powerful tool that can be used to understand, repair, improve, or create products. However, reverse engineering can be a complex and time-consuming process. By following the steps outlined in this article, you can make the reverse engineering process more efficient and effective.

Relevant Keyword Tags

- Reverse engineering

- Electronics

- Product design

- Circuit analysis

- Testing