Reverse Engineering Documentation

Reverse engineering documentation refers to the process of systematically understanding an existing system by deconstructing it into its component parts. It involves creating documentation that explains how a system works, what its purpose is, and how it is used. This documentation is essential for understanding a system’s architecture, functionality, and design principles. Reverse engineering documentation is also important for maintenance, troubleshooting, and further development of the system.

Reverse Engineering Documentation Process:

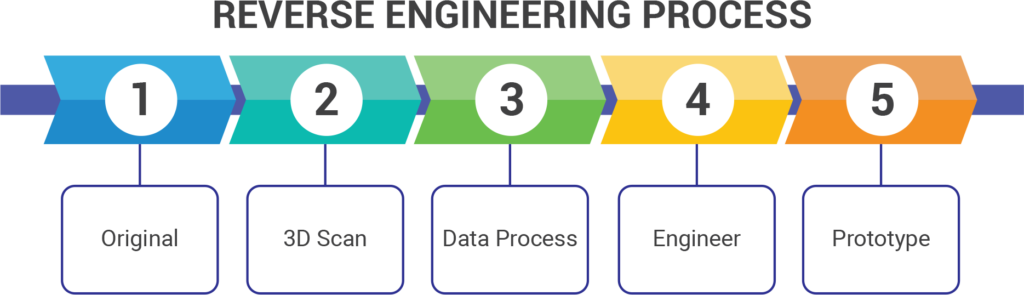

The reverse engineering documentation process typically involves several steps:

- Disassembly: Breaking down the system into its component parts, such as hardware, software, and firmware.

- Analysis: Examining the component parts to understand their function, interactions, and how they contribute to the overall system.

- Documentation: Creating detailed documentation that describes the system’s architecture, components, functionality, and interdependencies.

Types of Reverse Engineering Documentation:

Reverse engineering documentation can take various forms, depending on the system and the level of detail required. Some common types of reverse engineering documentation include:

- Technical Diagrams: Diagrams that depict the system’s architecture, component interactions, and data flow.

- Flowcharts: Detailed descriptions of the system’s processes, workflows, and decision-making logic.

- Use Cases: Descriptions of how the system is used by different users or entities.

- Technical Specifications: Detailed descriptions of the system’s requirements, capabilities, and limitations.

Benefits of Reverse Engineering Documentation:

Reverse engineering documentation offers numerous benefits, including:

- Enhanced Understanding: Improved comprehension of a system’s design, functionality, and implementation.

- Improved Maintenance and Troubleshooting: Easier identification and resolution of system issues and vulnerabilities.

- Support for System Improvements: Provides a basis for system optimization, enhancements, and further development.

- Historical Record: Preserves knowledge about the system’s evolution and provides a reference point for future generations.

Reverse engineering documentation is a valuable tool for understanding and managing complex systems. It helps ensure that systems are well-documented, maintainable, and adaptable to evolving needs.## Reverse Engineering Documentation

Executive Summary

Reverse engineering documentation is the process of extracting knowledge or design information from an existing product or system. Reverse engineers typically use this technique to create a similar product, improve upon an existing product, or understand how an existing product works. This process has a wide range of applications, from improving existing products or designing new ones, to understanding the inner workings of competitors’ products.

Introduction

Reverse engineering documentation is a complex and challenging process, but it can be essential for businesses that want to stay ahead of the competition. By understanding the design and functionality of existing products, businesses can identify areas for improvement which they can capitalize on and quickly create new products or improve upon existing ones.

FAQ

- What is the purpose of reverse engineering documentation?

- The purpose of reverse engineering documentation is to extract knowledge or design information from an existing product or system. This information can then be used to create a similar product, improve upon an existing product, or understand how an existing product works.

- What are the benefits of reverse engineering documentation?

- Reverse engineering documentation can provide a number of benefits, including:

- Reduced development time and cost

- Improved product quality

- Increased understanding of competitors’ products

- Reverse engineering documentation can provide a number of benefits, including:

- What are the challenges of reverse engineering documentation?

- Reverse engineering documentation can be a complex and challenging process. Some of the challenges include:

- Identifying the right product or system to reverse engineer

- Obtaining the necessary documentation and materials

- Understanding the design and functionality of the product or system

- Reverse engineering documentation can be a complex and challenging process. Some of the challenges include:

Top 5 Subtopics

- Product Design

- Manufacturing Process

- Materials

- Testing

- Quality Control

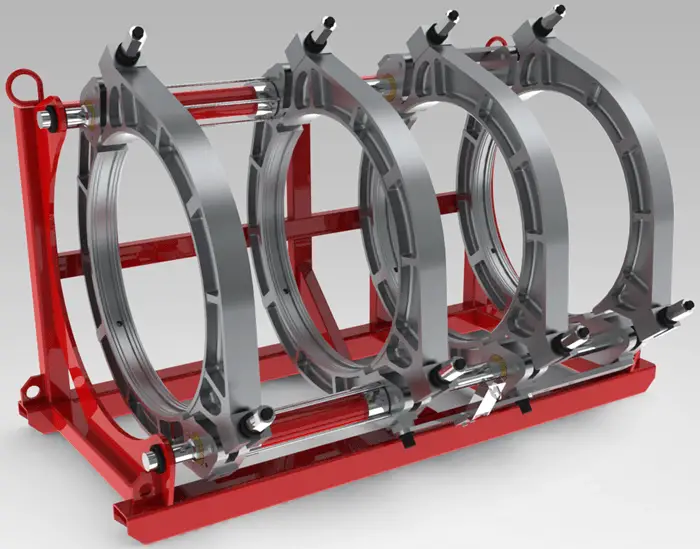

Product Design

Product design is the process of creating a new product or improving an existing product. Reverse engineers can use product design documentation to understand the design and functionality of a product. This information can then be used to create a similar product, improve upon an existing product, or understand how a competing product works.

- 4-6 Important Pieces of Product Design Documentation

- Product specifications

- Engineering drawings

- Computer-aided design (CAD) files

- Bill of materials (BOM)

- Test reports

- Quality control documentation

Manufacturing Process

The manufacturing process is the process of creating a product from raw materials. Reverse engineers can use manufacturing process documentation to understand how a product is made. This information can then be used to improve the manufacturing process, reduce costs, or create a similar product.

- 4-6 Important Pieces of Manufacturing Process Documentation

- Process flow diagrams

- Equipment specifications

- Work instructions

- Quality control procedures

- Safety procedures

- Environmental regulations

Materials

Materials are the substances that are used to create a product. Reverse engineers can use materials documentation to understand the properties of the materials that are used in a product. This information can then be used to select the right materials for a new product or improve the materials that are used in an existing product.

- 4-6 Important Pieces of Materials Documentation

- Material properties

- Material specifications

- Material testing reports

- Material safety data sheets (MSDSs)

- Environmental regulations

- Material suppliers

Testing

Testing is the process of evaluating the performance of a product. Reverse engineers can use testing documentation to understand how a product performs and to identify any potential problems. This information can then be used to improve the performance of a product or to identify potential problems before they occur.

- 4-6 Important Pieces of Testing Documentation

- Test plans

- Test procedures

- Test reports

- Quality control procedures

- Safety procedures

- Environmental regulations

Quality Control

Quality control is the process of ensuring that a product meets the required standards. Reverse engineers can use quality control documentation to understand the quality control procedures that are used to ensure that a product meets the required standards. This information can then be used to improve the quality control procedures or to ensure that a new product meets the required standards.

- 4-6 Important Pieces of Quality Control Documentation

- Quality control plans

- Quality control procedures

- Quality control reports

- Quality control standards

- Environmental regulations

- Quality control personnel

Conclusion

Reverse engineering documentation is a valuable tool for businesses that want to stay ahead of the competition. By understanding the design, functionality, and manufacturing process of existing products, businesses can identify areas for improvement, create new products, and stay ahead of the curve.

Keyword Tags

- Reverse Engineering Documentation

- Product Design

- Manufacturing Process

- Materials

- Testing

- Quality Control