Reverse Engineering Case Studies

Reverse engineering is the process of disassembling and analyzing a system to understand its functionality and design. It is often used to create a copy of a product or to learn how a system works.

There are many different case studies of reverse engineering, and each one provides insights into the process. Here are a few examples:

- The Boeing 777: In the early 1990s, Boeing began developing the 777 aircraft. The company used reverse engineering to learn from the lessons learned from the development of the 767 and 747 aircraft. This allowed Boeing to develop the 777 more quickly and efficiently.

- The iPhone: In 2024, Apple released the first iPhone. The iPhone was a revolutionary device that combined the functionality of a cell phone, an iPod, and a personal computer. However, Apple did not develop the iPhone from scratch. Instead, it used reverse engineering to learn from the designs of other smartphones, such as the Motorola RAZR and the BlackBerry.

- The Tesla Model S: In 2024, Tesla Motors released the Model S electric sedan. The Model S was a critical and commercial success, and it helped to establish Tesla as a leader in the electric vehicle market. However, Tesla did not develop the Model S from scratch. Instead, it used reverse engineering to learn from the designs of other electric vehicles, such as the Nissan Leaf and the Chevrolet Volt.

These are just a few examples of the many reverse engineering case studies that have been published. These case studies provide valuable insights into the process of reverse engineering and its applications.## Reverse Engineering Case Studies

Executive Summary

Reverse engineering involves disassembling a product, scrutinizing its structure and functionality, and recreating it. By analyzing industry benchmarks, this practice fuels innovation and sparks ideas for enhancements and modifications. Case studies, where organizations document their reverse engineering experiences and outcomes, serve as invaluable resources for teams embarking on similar endeavors.

Introduction

Reverse engineering empowers businesses by providing insights into competitive products, fostering a deeper understanding of industry trends, and guiding the development of improved offerings. It enables organizations to swiftly identify strengths and weaknesses, analyze innovative designs, and leverage valuable lessons for their own products or processes.

FAQs

Q: What is the purpose of a reverse engineering case study?

A: To document the process, challenges, and outcomes of a successful reverse engineering project to serve as a learning resource for others.

Q: Which industries can benefit from reverse engineering case studies?

A: Virtually any industry can leverage case studies to improve product development, from manufacturing and engineering to software and technology.

Q: How can I find reverse engineering case studies?

A: Search online, explore academic databases, and reach out to industry contacts who may have access to relevant studies.

5 Key Subtopics of Reverse Engineering Case Studies

1. Industry and Product Analysis

- Competitive Landscape: Examining the industry landscape, key competitors, and their products’ market positioning.

- Product Specifications: Investigating the product’s technical specifications, materials, and construction methods.

- Market Research: Assessing consumer feedback, industry reviews, and market trends related to the product.

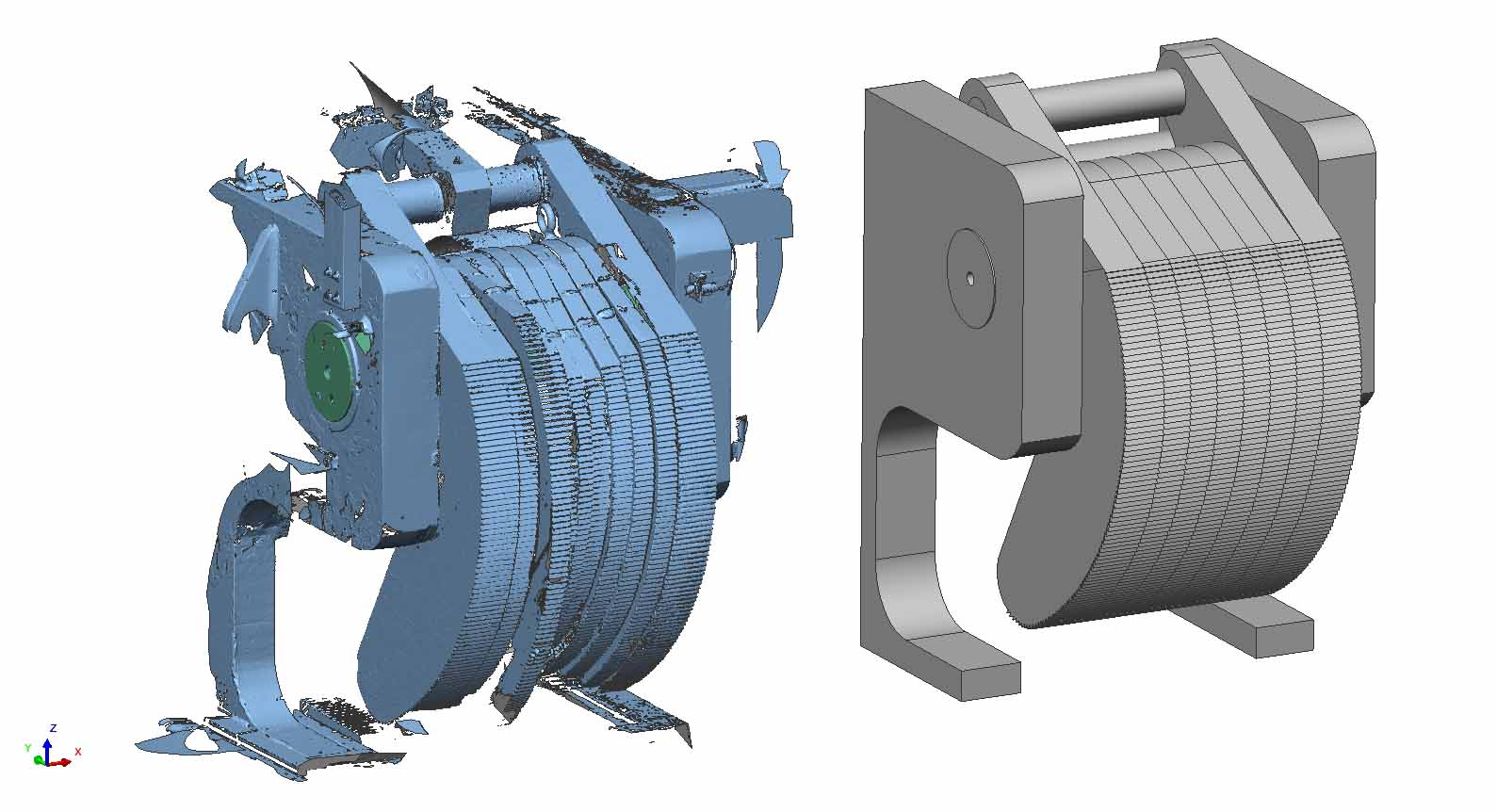

2. Disassembly and Documentation

- Product Decomposition: Breaking the product down into its constituent parts and documenting their assembly and interconnections.

- Dimensional Analysis: Measuring and recording the dimensions, tolerances, and geometry of each component.

- Component Inspection: Closely examining each component for materials, manufacturing techniques, and underlying engineering principles.

3. Design and Innovation

- Benchmarking: Comparing the product’s design and functionality to similar products or industry benchmarks.

- Innovation Analysis: Identifying unique features, novel designs, or innovative solutions incorporated into the product.

- IP Identification: Analyzing the product for patented technologies or proprietary designs to avoid potential infringement.

4. Cost and Manufacturing

- Materials Analysis: Determining the cost and availability of the materials used in the product’s manufacturing.

- Manufacturing Process Evaluation: Studying the production methods, tooling, and techniques employed in manufacturing the product.

- Supply Chain Mapping: Identifying the suppliers of components and materials, assessing their reliability and cost-effectiveness.

5. Quality and Testing

- Quality Control Assessment: Evaluating the product’s quality control standards, testing procedures, and compliance with industry regulations.

- Performance Testing: Conduct experiments to analyze the product’s performance, reliability, and durability under various conditions.

- Comparative Analysis: Comparing the product’s performance to similar products or established industry standards.

Conclusion

Reverse engineering case studies are invaluable tools for businesses seeking to enhance their product development processes. By leveraging insights from successful projects, organizations can swiftly identify areas for improvement, foster innovation, and gain a competitive edge. By thoroughly analyzing the industry, product, manufacturing, and testing aspects, teams can achieve greater precision and generate more informed decisions. Reverse engineering case studies empower organizations to build better products, optimize processes, and drive industry advancement.

Keywords

- Reverse engineering

- Case studies

- Product development

- Innovation

- Benchmarking