Step 1: Acquire the Product

Obtain the physical product or digital files, such as software or documentation, to be reverse engineered.

Step 2: Disassemble and Analyze

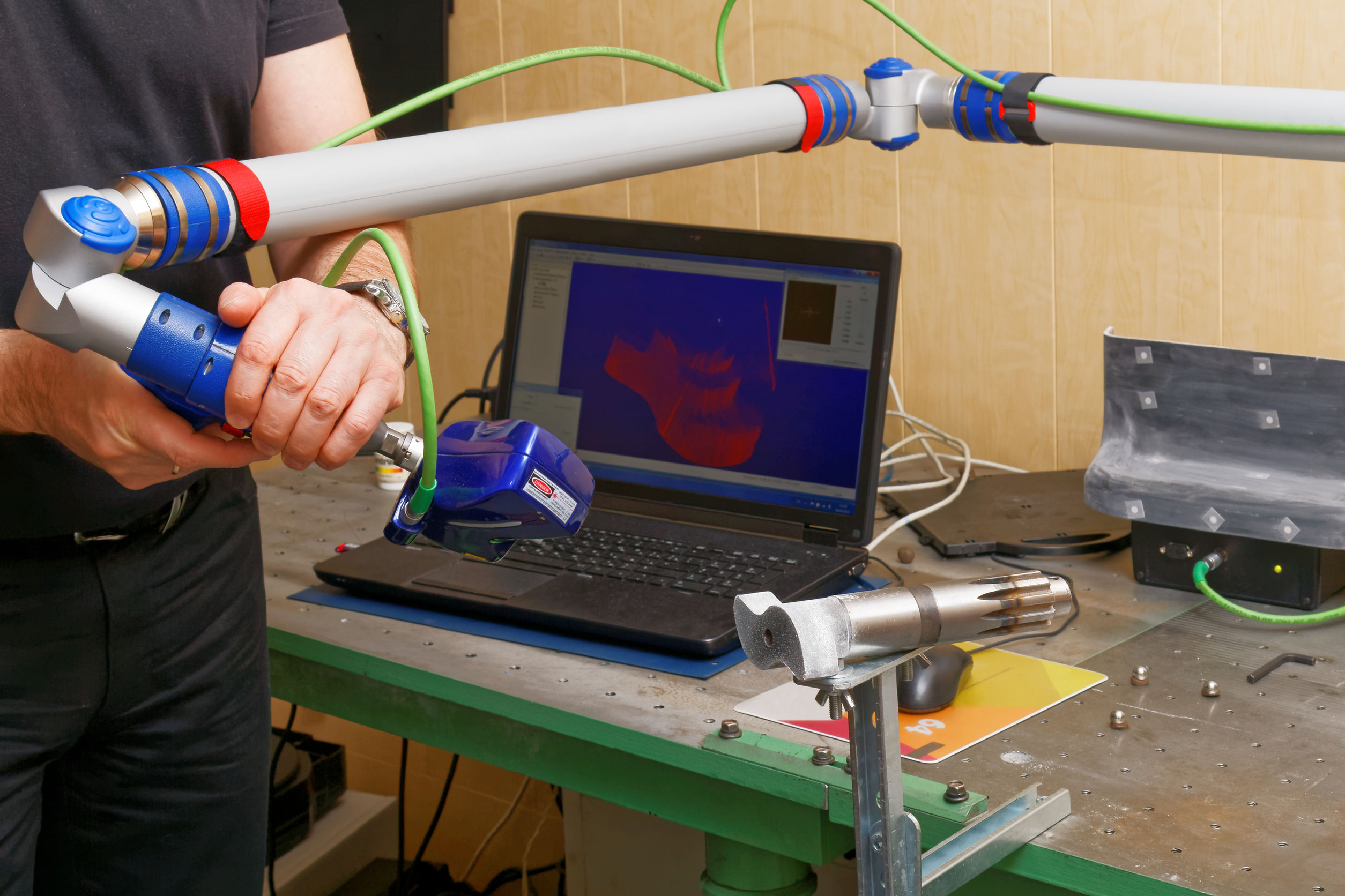

Disassemble the product into its component parts. Analyze each part, identifying its materials, structure, and functionality.

Step 3: Identify Key Features and Mechanisms

Determine the core features and mechanisms that the product relies on for its operation. Focus on understanding how the components interact with each other.

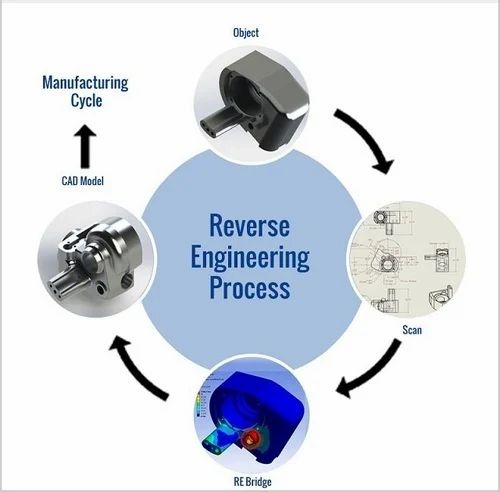

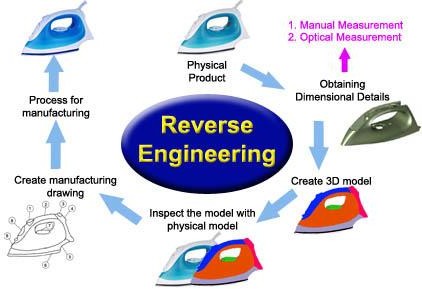

Step 4: Create Functional Diagrams

Develop diagrams that illustrate the overall functionality of the product and its subsystems. This will help visualize the flow of data and identify critical processes.

Step 5: Reverse Engineer Software

If software is involved, decompile or dissemble the code to understand its structure and algorithms. Identify key modules, variables, and control flow.

Step 6: Document the Design

Create detailed technical documentation that describes the product’s design, construction, and operation. This documentation becomes the basis for future modifications or enhancements.

Step 7: Prototyping and Testing

Based on the analysis, create prototypes to test the accuracy and functionality of the reverse-engineered design. Conduct thorough testing to ensure the product performs as expected.

Step 8: Continuous Improvement

The reverse engineering process is iterative, allowing for ongoing improvements and optimizations. Utilize feedback from testing and real-world usage to refine the design and ensure the product remains relevant and efficient.