Reverse Engineering a Product

Reverse engineering involves dissecting an existing product to understand its design, functionality, and construction methods. It is a valuable technique for learning about existing technologies, identifying areas for improvement, and gaining insights into the design choices made by others. The process involves several steps:

-

Disassembly: The product is disassembled to access its internal components and mechanisms. This requires careful examination and documentation of the assembly order, wiring, and connections.

-

Analysis: The individual components are examined to determine their function, materials, and tolerances. This involves studying their shape, dimensions, and materials used. Functional testing may be necessary to understand how the components interact.

-

Documentation: The findings from the analysis are recorded through sketches, diagrams, and written notes. These documents provide a comprehensive representation of the product’s design and serve as a reference for future analysis.

-

3D Modeling: Using the documentation from the analysis, a digital 3D model of the product can be created using CAD (Computer-Aided Design) software. This model provides a more accurate representation of the product’s shape and dimensions.

-

Simulation: The 3D model can be used for simulation studies to predict the product’s behavior under various conditions. This can help identify potential issues or areas for improvement.

-

Prototyping: If desired, a physical prototype of the product can be fabricated based on the 3D model. This prototype can be used for further testing, modification, or as a reference sample.

Reverse engineering is particularly valuable for understanding complex products or technologies. It can provide insights into the design process, materials selection, and manufacturing techniques employed. The resulting documentation and 3D model can be used for further product development, innovation, or quality improvement initiatives.## How To Reverse Engineer A Product

Executive Summary

This article will present the definition of reverse engineering, as well as the steps taken when it is used. It will also discuss many benefits and reasons why reverse engineer a product.

Introduction

As a business owner, you may often wonder how your competitors are creating great products in your industry. Reverse engineering can be a simple way to gain insight into your competitor’s business and their products. This article will help you understand the steps of reverse engineering, why you may want to perform it, and many benefits of the process.

FAQ

What is Reverse Engineering?

Why would I want to Reverse Engineer a Product?

What are some benefits of reverse engineering?

5 Subtopics

1. Definition of Reverse Engineering

Reverse engineering is a process of taking a product apart and analyzing its features to understand how it works. This information can then be used to create a new product that is similar to the original, or to improve upon the original design.

a. Types of reverse engineering:

- Software reverse engineering – This involves taking apart a software program to understand how it works.

- Hardware reverse engineering– This involves taking apart a physical product to understand how it works.

- Biological reverse engineering – This involves taking apart a biological system to understand how it works.

b. Why reverse engineer a product?

- To create a new product that is similar to the original

- To improve upon the original design

- To learn how the product works

- To find security vulnerabilities

- To identify and understand imperfections

2. Steps to Reverse Engineer a Product

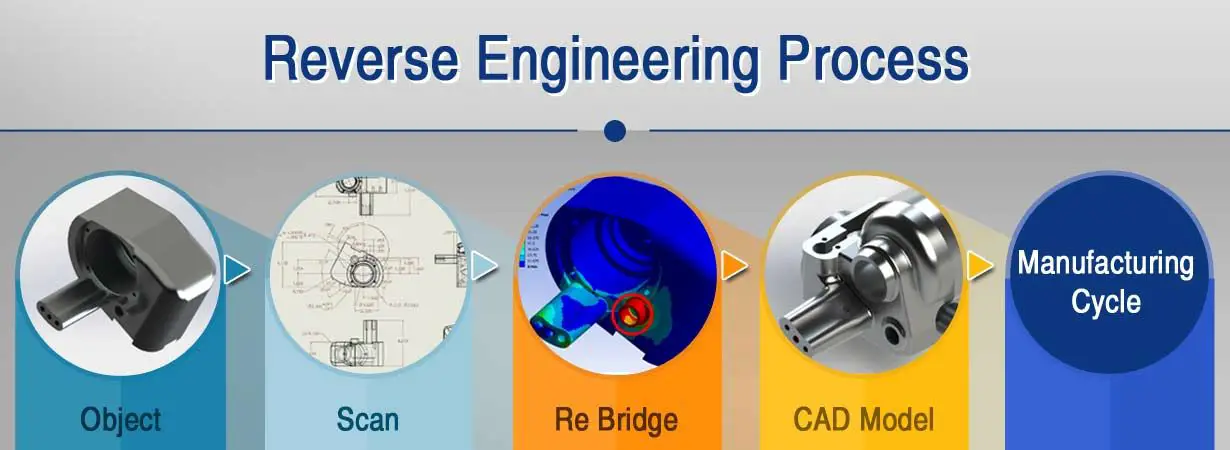

The process of reverse engineering a product typically involves the following steps:

a. Disassembling the product

The first step is to disassemble, which is taking the product apart into its individual components. This will give you a better understanding of how the product is put together and how the different components work together.

b. Analyzing the components

Once you have disassembled the product, you need to analyze the individual components. This will involve examining the components’ shapes, sizes, materials, and functions. You should also look for any markings or labels on the components. Those markings can help you identify the components and find more information about them.

c. Creating a model of the product

Once you have analyzed the components, you need to create a model of the product. This model can be a physical model, a computer-aided design (CAD) model, or a software model. The model will help you visualize how the product works and how the different components fit together.

d. Testing the model

Once you have created a model of the product, you need to test it to make sure it works. This may involve testing the product’s functionality, performance, and durability.

e. Refining the model

Once you have tested the model, you may need to refine it. This may involve making changes to the design of the product or to the way it is assembled.

3. Benefits of Reverse Engineering

There are several benefits to reverse engineering a product, including:

a. Increased understanding of the product

Reverse engineering a product can give you a deep understanding of how the product works. This knowledge can be used to improve the product, to create new products, or to simply satisfy your curiosity.

b. New product development

Reverse engineering can be a great way to develop new, innovative, and competitive products. By understanding how a competitor’s product works, you can identify its strengths and weaknesses, and develop new and creative ways to meet your customers’ needs.

c. Identification and exploitation of undetected weakness and vulnerability

Products, especially software, are getting more complex. Therefore, undetected weaknesses and vulnerabilities find their way into products. Reverse engineering can help to expose and exploit them to improve security.

4. Cost reduction

Reverse engineering can help you reduce the cost of developing new products. By understanding how a competitor’s product works, you can avoid making the same mistakes and learn from their successes.

5. Competitive advantage

Reverse engineering can give you a competitive advantage over your competitors. By understanding how their products work, you can develop new products to differentiate yourself in the market.

Conclusion

Reverse engineering is a process that can be used to gain a competitive advantage or improve your own products. By understanding the steps involved in reverse engineering, the benefits of the process, and the reasons why you may want to perform it, you can make informed decisions about whether or not to reverse engineer a product.

Keyword Tags

- reverse engineering

- product development

- competitive advantage

- cost reduction

- new product development