From Concept to Product: Reverse Engineering in Design

Reverse engineering, the process of dissecting an existing product to understand its design, is a valuable technique employed in various industries, including product design. This approach involves analyzing the structure, function, and components of a product to gain insights into its design principles and manufacturing processes. By deconstructing a product, designers can extract valuable knowledge and inspiration, leading to innovative and improved designs.

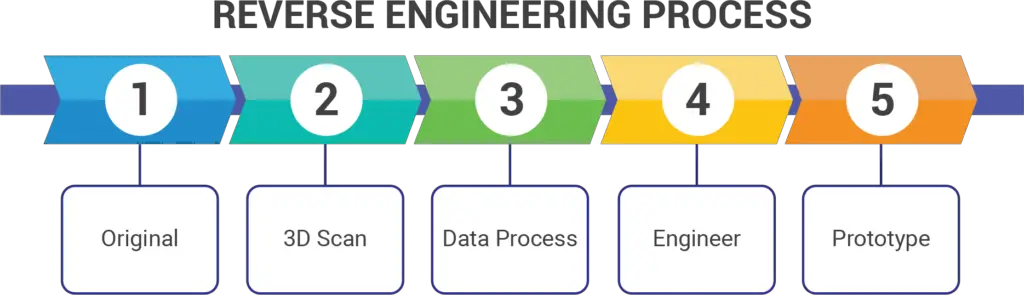

Key Steps in Reverse Engineering for Product Design

- Product Selection:

The first step is to identify and select the product that will be analyzed. This selection is often influenced by factors such as the product’s relevance to the designer’s project, its complexity, and its potential for improvement.

- Disassembly and Documentation:

The selected product is carefully disassembled into its individual components. During this process, each component is examined, and its characteristics, such as materials, dimensions, and surface finishes, are documented. This detailed documentation serves as a valuable reference for subsequent analysis.

- Analysis of Components:

The individual components are analyzed to understand their functions, interactions, and relationships within the product. Designers evaluate factors such as the choice of materials, manufacturing processes, and design features to identify potential areas for improvement or optimization.

- Reconstruction and Testing:

After analyzing the components, the product is reconstructed to verify the accuracy of the analysis and to test its performance against the original product. This step allows designers to identify any discrepancies or errors in their understanding of the product’s design.

- Ideation and Improvement:

Drawing upon the knowledge gained through the reverse engineering process, designers brainstorm ideas for improving the product’s design, functionality, or manufacturing process. This ideation phase is supported by the understanding of the original product’s strengths and weaknesses.

- Prototyping and Validation:

The proposed design improvements are implemented in the form of prototypes. These prototypes undergo rigorous testing and validation to evaluate their performance and to ensure they meet the desired requirements.

- Final Product Design:

Based on the findings from the prototyping and testing phase, the final product design is created. This design incorporates the identified improvements while maintaining the core functionality of the original product.

Benefits of Reverse Engineering in Product Design

- Innovation and Competitiveness:

Reverse engineering fosters a culture of innovation by encouraging designers to challenge existing design solutions and explore novel approaches. By understanding competing products, designers can identify opportunities for differentiation and gain a competitive edge.

- Cost Reduction and Efficiency:

By analyzing existing designs, manufacturers can identify areas for cost reduction and efficiency improvements. Reverse engineering can uncover inefficiencies in the manufacturing process and lead to the development of more streamlined production methods.

- Quality Improvement:

Understanding the design and manufacturing processes of existing products allows designers to make informed decisions about materials, tolerances, and assembly techniques. This knowledge can contribute to the development of more durable and reliable products.

- Design Education and Training:

Reverse engineering provides valuable hands-on experience for design students and professionals, allowing them to learn from the successes and failures of existing products. The process teaches the importance of design principles, material selection, and manufacturing considerations.

In conclusion, reverse engineering is a powerful tool that enables designers to gain valuable insights into existing products, inspiring innovation, improving quality, and enhancing competitiveness. By systematically deconstructing and analyzing products, designers can unlock the secrets of successful designs, leading to the development of innovative and improved solutions.# From Concept To Product: Reverse Engineering In Design

Executive Summary:

Reverse engineering is a design process used to understand how a product works by taking it apart and analyzing its components and functionality. It’s a powerful tool for organizations, enabling them to gain insights into existing products, improve their own designs, and stay ahead of the competition. This paper explores the process of reverse engineering in design, its benefits, and strategies for successful implementation.

Introduction:

Reverse engineering has been part of industrial practice for decades but is progressively more relevant as organizations seek to innovate rapidly. This paper aims to provide a comprehensive understanding of reverse engineering and its significance in the highly competitive design industry.

Subtopics:

1. Understanding Reverse Engineering

Reverse engineering involves disassembling an existing product, analyzing its components, and understanding its functionality and design principles. It is a method of learning from successful products and incorporating their attributes into new designs.

- Key Points:

- Disassembly: Breaking down the product into its individual components.

- Analysis: Examining each component’s function, materials, and design.

- Documentation: Recording observations and data throughout the process.

2. Benefits of Reverse Engineering

Reverse engineering yields valuable insights for organizations, enhancing design processes and improving product offerings.

- Key Points:

- Learning from Competitors: Understanding competitors’ products to find strengths and weaknesses.

- Innovation: Gaining inspiration for new design solutions.

- Cost Reduction: Identifying areas for optimization and cost-effective manufacturing.

- Quality Improvement: Identifying potential problems and implementing solutions.

3. Strategies for Successful Implementation

Structured and methodical approaches ensure successful reverse engineering.

- Key Points:

- Proper Documentation: Recording observations, measurements, and insights.

- Functional Analysis: Understanding the functionality of each component.

- Material Analysis: Identifying the materials used and their properties.

- Design Principles: Extracting design principles and patterns.

4. Common Challenges in Reverse Engineering

Reverse engineering can be challenging; being aware of potential hurdles allows for effective planning and mitigation.

- Key Points:

- Intellectual Property Infringement: Ensure that the reverse engineering process does not infringe on intellectual property rights.

- Complexity: Reverse engineering complex products requires specialized expertise.

- Availability of Information: Gathering accurate and comprehensive information can be challenging.

5. Tools and Technologies for Reverse Engineering

Advanced tools and technologies facilitate efficient and accurate reverse engineering processes.

- Key Points:

- 3D Scanning: Non-destructive method for capturing product geometry.

- Computer-Aided Design (CAD) Software: Modeling and analyzing product components.

- Finite Element Analysis (FEA) Software: Predicting product performance.

Conclusion:

Reverse engineering is a valuable tool in the design industry, enabling organizations to learn from existing products, drive innovation, and improve quality. By understanding the process, utilizing appropriate strategies, and leveraging appropriate tools and technologies, organizations can gain a competitive edge and accelerate design development.

Keyword Phrase Tags:

- Reverse Engineering

- Product Design

- Design Innovation

- Competitive Analysis

- Product Improvement

Thank you for this amazing article. It has made me think again about the phases and steps of mechanism design.

You’ve got to be kidding me. This is the most asinine thing I’ve ever read. Everyone knows that reverse engineering is cheating

This article provides a comprehensive overview of the reverse engineering process in design. The inclusion of real-world examples makes it even more informative.

I disagree with the author’s claim that reverse engineering is always the best approach. In some cases, it may be more efficient to start from scratch.

Oh, the irony! An article about reverse engineering using reverse engineering to make its point. How meta.

I’m not sure I understand what the author is trying to say. Can someone explain this to me in simpler terms?

Who needs reverse engineering when you can just use your imagination?

This is a great article, but I think it could be improved by including more visuals. A diagram or two would really help to illustrate the concepts.

I’m not convinced that reverse engineering is always the best approach. Sometimes it’s better to start from scratch with a clean slate.