AI-Powered Robotics: Changing the Face of Manufacturing and Logistics

The integration of artificial intelligence (AI) into robotics has significantly transformed the manufacturing and logistics industries. AI-powered robots are equipped with advanced algorithms and sensors that enable them to perform tasks with greater efficiency, precision, and autonomy. This technological advancement has several implications for these industries:

Increased Productivity: AI-powered robots can operate 24/7 without fatigue, increasing production capacity. Their ability to perform repetitive and hazardous tasks frees up human workers to focus on more complex and creative responsibilities, resulting in higher overall productivity.

Improved Quality and Consistency: AI-powered robots use precise sensors and algorithms to monitor production processes, ensuring a consistent and high-quality output. By eliminating human error, these robots can maintain high standards and minimize defects, leading to enhanced customer satisfaction.

Enhanced Flexibility: Traditional robots are often programmed for specific tasks, limiting their adaptability to changing production or logistical needs. AI-powered robots, however, can be reprogrammed and redeployed quickly and seamlessly. This flexibility allows manufacturers and logistics companies to respond to fluctuating demand and customize production processes more efficiently.

Reduced Operational Costs: AI-powered robots offer substantial savings in labor costs, maintenance expenses, and energy consumption. They can operate with minimal human supervision, reducing the need for additional staff. By optimizing production processes, they also contribute to lower waste and increased energy efficiency.

Safety and Security Enhancements: AI-powered robots can be equipped with sensors that detect safety hazards and prevent accidents. They can also be used for surveillance and security purposes, enhancing the overall safety and security of manufacturing facilities and logistical operations.

Transforming Jobs: AI-powered robotics has the potential to transform the roles of human workers in these industries. While some jobs may be automated, it also creates new opportunities for workers to adapt and develop new skills in areas such as robot programming, maintenance, and data analysis.

In conclusion, AI-powered robotics is revolutionizing manufacturing and logistics by enabling increased productivity, improved quality, enhanced flexibility, reduced costs, and heightened safety. By leveraging the capabilities of these advanced systems, businesses can gain a competitive edge, optimize operations, and pave the way for a transformed future of these crucial sectors.# Ai-powered Robotics: Changing The Face Of Manufacturing And Logistics

Executive Summary

The integration of AI-powered robotics in manufacturing and logistics is revolutionizing these industries, bringing about enhanced efficiency, increased productivity, and reduced operating costs. This article explores the significant role of AI-powered robotics in transforming these sectors, highlighting key applications, benefits, and future trends.

Introduction

The convergence of artificial intelligence (AI) and robotics has propelled us into an era marked by transformative technological advancements. AI-powered robotics, in particular, is poised to reshape the very fabric of manufacturing and logistics. By leveraging the power of AI, robots can now perform complex tasks with unprecedented accuracy, efficiency, and autonomy.

FAQs

-

What is AI-powered robotics?

- AI-powered robotics refers to the integration of AI algorithms and technologies with robotic systems, enabling them to perform tasks that were once solely reserved for human workers.

-

How does AI-powered robotics benefit manufacturing and logistics?

- AI-powered robots enhance precision, reduce manual labor, streamline processes, and improve decision-making, leading to increased productivity and efficiency.

-

What are the limitations of AI-powered robotics?

- While AI-powered robots offer numerous advantages, they also come with limitations such as high initial investment costs, the need for skilled operators, and potential job displacement concerns.

Subtopics

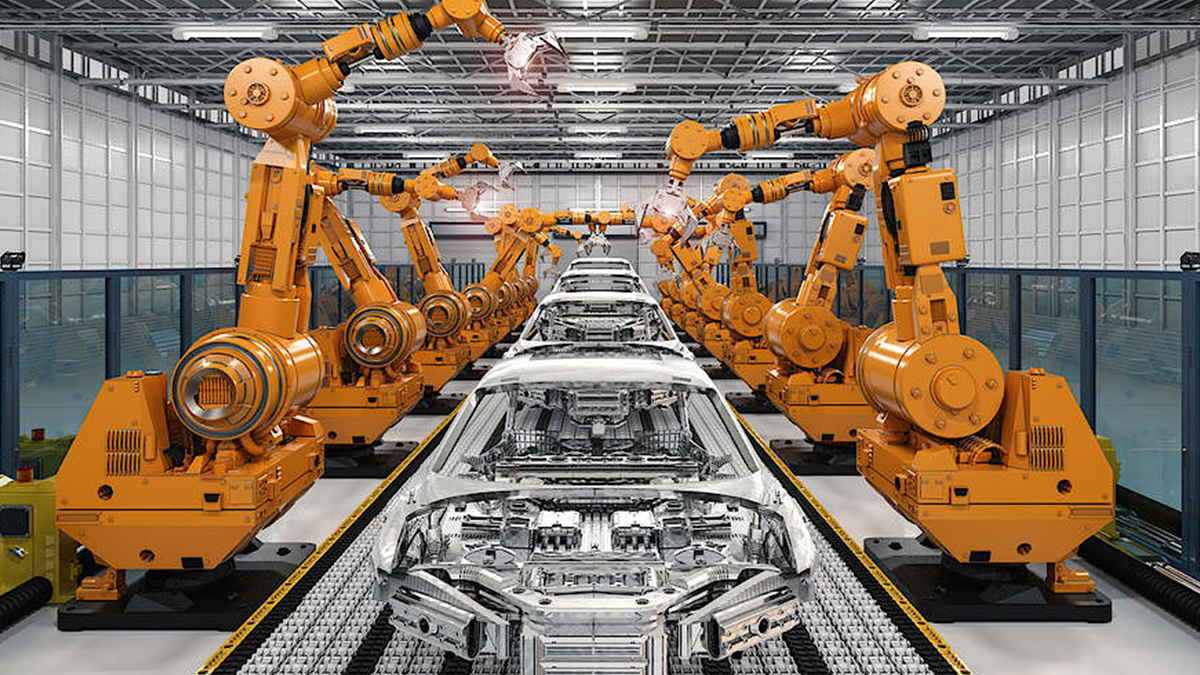

1. Precision and Efficiency in Manufacturing

- Robotic assembly: AI-powered robots are employed in assembly lines to assemble products with greater precision and speed.

- Quality control: Robots equipped with AI can perform rigorous quality inspections, identifying defects that might escape human detection.

- Inventory management: AI-powered robots streamline inventory management by tracking stock levels, managing orders, and optimizing warehouse operations.

- Predictive maintenance: Robots use AI to analyze data and predict equipment maintenance needs, minimizing downtime and maximizing production efficiency.

2. Automation and Optimization in Logistics

- Autonomous guided vehicles (AGVs): AGVs navigate warehouses and distribution centers autonomously, transporting goods efficiently and reducing the need for manual labor.

- Automated storage and retrieval systems (AS/RS): AI-powered AS/RS systems optimize storage and retrieval processes, reducing lead times and increasing space utilization.

- Order fulfillment: AI-powered robots collaborate with humans to process orders faster and more accurately, reducing delivery times and improving customer satisfaction.

- Route optimization: Robots use AI algorithms to determine the most efficient delivery routes, minimizing travel time and fuel consumption.

3. Advanced Data Analytics and Decision-Making

- Real-time data monitoring: AI-powered robotics collect vast amounts of data, providing real-time insights into production and logistics processes.

- Predictive analytics: Robots use AI to analyze data and predict future trends, helping businesses make informed decisions about production planning, inventory management, and logistics operations.

- Machine learning (ML): ML algorithms continuously improve the performance of AI-powered robots over time, enhancing their decision-making capabilities.

- Adaptive learning: Robots equipped with AI can adapt to changing conditions, adjust their behavior, and optimize processes autonomously.

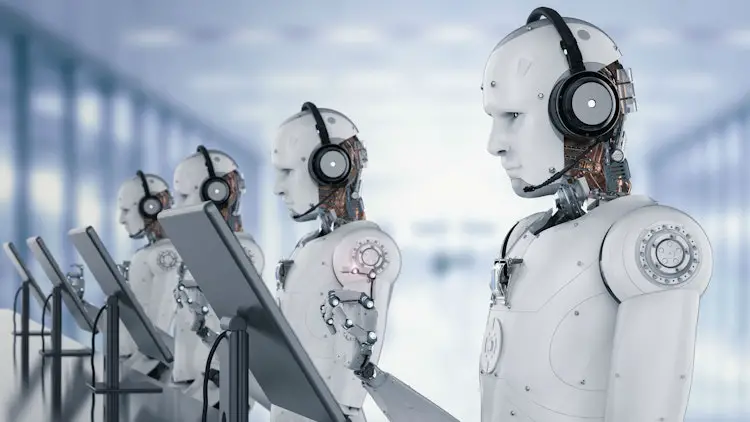

4. Workforce Transformation

- Increased productivity: AI-powered robots handle repetitive and labor-intensive tasks, freeing up human workers to focus on higher-value tasks.

- New job opportunities: The adoption of AI-powered robotics creates new job opportunities in areas such as robotics engineering, data analysis, and maintenance.

- Reskilling and upskilling: Workers may need to reskill or upskill to adapt to the changing job landscape brought about by AI-powered robotics.

- Improved safety: Robots take on hazardous or repetitive tasks, reducing the risk of workplace accidents and improving worker safety.

5. Future Trends

- Collaborative robots (cobots): Cobots work alongside human workers, enhancing their capabilities and enabling greater flexibility in manufacturing and logistics.

- Edge computing: AI-powered robotics will increasingly leverage edge computing for real-time data processing and decision-making.

- AI-driven simulation: AI will be used to simulate manufacturing and logistics processes, enabling businesses to optimize operations and reduce risk.

- Blockchain integration: Blockchain technology will play a role in securing data and ensuring the integrity of AI-powered robotics systems.

Conclusion

The integration of AI-powered robotics in manufacturing and logistics is not just a technological shift; it is a fundamental transformation that has the potential to redefine these industries. By harnessing the precision, efficiency, and automation capabilities of AI-powered robots, businesses can unlock new levels of productivity, reduce costs, and gain a competitive edge. As technology continues to advance, we can expect AI-powered robotics to play an even more significant role in shaping the future of manufacturing and logistics.

Keyword Tags

- AI-powered robotics

- Manufacturing automation

- Logistics optimization

- Data analytics

- Workforce transformation